Metal parts are extremely widely used in the industrial field, and their dimensional accuracy is directly related to the performance and use of the product. For example, in mechanical manufacturing, the dimensional deviation of a part may lead to assembly difficulties or unstable operation; in the aerospace field, small dimensional changes may affect the safety and stability of the aircraft. It can be seen that the accurate measurement of the size of metal parts is of vital importance.

Detecting Difficulties:

1、Product diversity: metal parts have a variety of shapes, both simple geometric shapes and complex curved structures, which increases the difficulty of measurement.

2, the surface is not smooth: the surface of the metal material may have roughness, oxidized layer and other factors, these will affect the accuracy of the measurement results.

The traditional measurement methods, such as micrometers and vernier calipers, are cumbersome and susceptible to human error. In view of these difficulties, image measuring instrument with its unique advantages in the metal parts size inspection stands out.

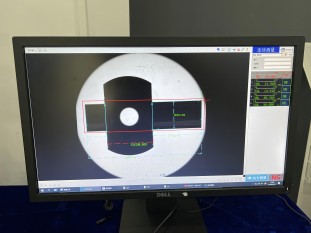

High-precision Measurement: Image Measuring Instrument adopts machine vision technology, combined with high-precision image analysis algorithms, which is able to realize fast and accurate measurement of metal parts. Whether it is simple geometry or complex curved surface structure, the image measuring instrument can easily deal with it.

Repeatability and Stability: Image measuring instrument has high repeatability and stability. Due to the automated measurement method, the interference of human error is avoided, making the measurement results more reliable. In addition, image measuring instrument also has data traceability, can easily record and analyze the measurement data, for quality control and process improvement to provide strong support.

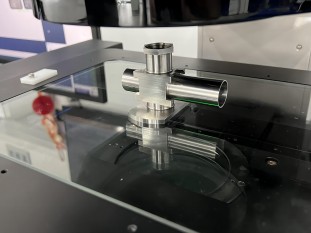

Simple operation: The Image Gauge is simple to operate and easy to use. Users only need to place the metal parts on the carrier table of the measuring instrument, and can complete the measurement task through simple operation. Meanwhile, the measurement data can be displayed on the screen in real time, which is convenient for users to observe and record.

Wide range of applications: The image measuring instrument also has a wide range of applications. It can be used not only for the size measurement of metal parts, but also for surface quality inspection, contour measurement and defect detection and other aspects. This makes the image measuring instrument in industrial production has a very high practical value.

Test Results:

POMEAS image measuring instrument plays an important role in the dimensional inspection of metal parts with its accurate, efficient and stable characteristics. With the continuous development of industrial technology, image measuring instrument will be applied in more fields to provide strong support for industrial production.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com