3D White Light Interference Profiler, also known as White Light Interferometer or Non-Contact 3D Surface Profiler, is an optical instrument based on the principle of interference to measure the difference of light paths and thus to determine the relevant physical quantities.

First of all, the light source emitting part of the profilometer adopts high brightness LED light source or laser light source, which emits parallel or focused light. These rays of light, when projected onto the surface of the object to be measured, will produce reflection, diffuse reflection or transmission phenomena, forming the outline of the object.

Second, the light projection section focuses or projects the light onto the surface of the object under test through an optical lens or reflector. In this process, the uniformity, brightness and focus of the light need to be ensured in order to obtain clear and accurate contour information.

Third, the light spot receiving section utilizes devices such as CCD cameras or photoelectric sensors to receive and image light spots on the surface of the object under test. These devices convert the light spot formed by the object contour into an electrical signal that is transmitted to a signal processing system for processing and analysis.

In the signal processing link, the system processes and analyzes the received light spot signals through image processing algorithms, digital signal processing techniques and data analysis methods. Among them, the light emitted from the light source is divided into two beams by the beam splitter prism after beam expansion and collimation, one beam is reflected back by the measured surface, and the other beam is reflected by the reference mirror. The two beams of reflected light finally converge and interferes, and the microscope converts the topography of the measured surface into an interference fringe signal. By measuring the changes in the interference fringes, the system is able to accurately measure the three-dimensional shape of the object surface.

In addition, the white light interferometer uses optical interference technology, precision Z-direction scanning module and excellent 3D reconstruction algorithms to form a measurement system, and the main measurement parameters include roughness, step height, and geometric profile. It is capable of non-destructively inspecting precision machined surfaces in a non-contact manner and visually displaying surface texture features in a 3D data map.

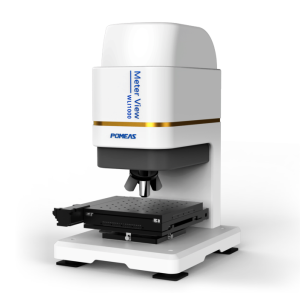

POMEAS 3D White Light Interference Profiler realizes high-precision non-contact measurement of object surface topography through its unique working principle and advanced technology, providing an effective solution for surface quality inspection of various precision devices and components.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com