In-line measuring instrument measuring 8MM standard bar application case

In the field of precision measurement in the manufacturing industry, standard rods are widely used as an important calibration tool to ensure the accuracy and reliability of measurement equipment. This application case will introduce how to use an in-line measuring instrument to accurately measure an 8MM standard bar and discuss its application value in quality control and process improvement.

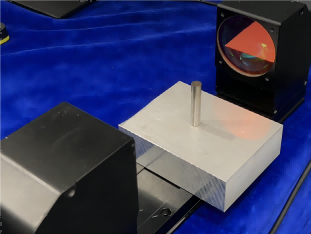

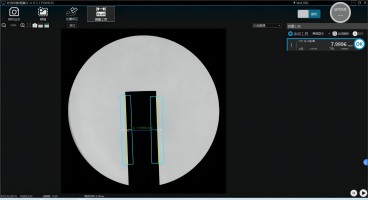

The 8MM standard bar is placed on the measuring platform of the on-line measuring instrument and the measurement program is started. The in-line measuring instrument performs non-contact measurement on the standard bar by means of a high-precision sensor and displays the measurement data in real time.

During the measurement process, we paid close attention to the stability of the measurement data and recorded the measurement results several times. By analyzing the measurement data, we found that the repeatability of the measurement results was good and the deviation range was within the acceptable range, thus verifying the accuracy of the online measuring instrument.

Verified the accuracy of the measuring equipment: By comparing the nominal size of the standard bar with the measurement results, we confirmed that the accuracy of the in-line measuring instrument is good and can be used with confidence for subsequent workpiece measurements.

Improved quality control: Measuring the standard bar with the in-line measuring instrument helps us to find the deviation of the measuring equipment in time, so that we can make adjustments and calibrations in time to ensure the accuracy and consistency of the dimensions of the workpieces, and improve the level of product quality control.

Supported process improvement: Through the accurate measurement of standard bars, we can obtain more accurate data on workpiece dimensions, which provides strong support for process improvement. Based on this data, we can optimize machining parameters and improve processes to increase productivity and product quality.

This application case of measuring 8MM standard bar by on-line measuring instrument demonstrates its important application value in quality control and process improvement. Through accurate measurement and data analysis, we can ensure the accuracy of measuring equipment, improve the level of product quality control and provide strong support for process improvement.

In the future, with the continuous development of the manufacturing industry and the continuous progress of technology, high-precision measuring equipment such as on-line measuring instruments will be applied in more fields. We will continue to explore and research the measurement principles and application methods of these devices to continuously improve the measurement accuracy and efficiency and contribute more to the development of the manufacturing industry.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com