ITO, or Indium Tin Oxide, is a transparent, conductive thin film material that is widely used in liquid crystal displays, touchscreens, solar cells, and other applications. Since ITO films need to go through several stages in the production process, such as coating, polishing and cutting and grinding, these stages may introduce minor defects such as water droplet defects, stains, bubbles and scratches. These defects can seriously affect the performance of ITO film, which in turn affects the quality and stability of its final product. Therefore, efficient and accurate visual inspection of ITO films is particularly important.

Detection Program:

Lens selection: POMEAS 4K zoom lens features high resolution, large target surface, and infinitely adjustable magnification, which can realize accurate identification of fine defects on the surface of ITO film. The lens supports a maximum sensor size of 1 inch, a working distance of 80mm, and a magnification range of 0.68X~5X, which is suitable for the inspection of ITO films of different sizes and thicknesses.

Light source design: In order to obtain clear inspection images, we use a ring bottom light source. This light source can provide uniform lighting conditions and reduce shadows and reflections, making defects easier to identify.

Image Acquisition and Processing: Images of ITO films are acquired by a high-resolution vision system, and image processing algorithms are used for image preprocessing, feature extraction and defect recognition. The algorithm can automatically detect and mark the defects on the surface of ITO film, realizing fast and accurate detection.

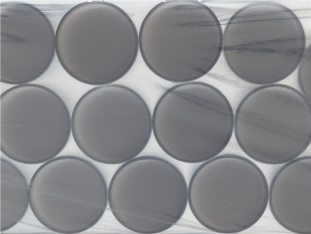

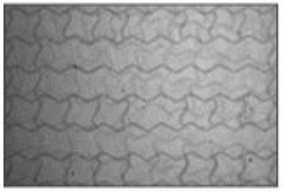

Test Results:

Program Advantages:

High Resolution Imaging: The POMEAS 4K zoom lens supports 4K level of horizontal resolution, which is capable of capturing subtle defects on the surface of ITO films, improving the accuracy and reliability of the inspection.

Large field of view: Compared to traditional zoom systems, the field of view of the POMEAS 4K zoom lens is increased by more than 1.45X, enabling it to cover a larger area in a single inspection and improve inspection efficiency.

Adjustable magnification: The magnification range of the lens can be adjusted according to the actual needs, which is suitable for the inspection of ITO films of different sizes and thicknesses, providing higher flexibility and applicability.

Compact and easy to operate: POMEAS 4K zoom lens adopts modular design, which is compact and easy to install and debug. Meanwhile, the vision system is simple to operate and easy to integrate into existing production lines for automated inspection.

The application of POMEAS 4K zoom lens in ITO inspection can realize efficient and accurate identification of fine defects on the surface of ITO film, improve product quality and production efficiency, and provide a strong guarantee for the production and application of ITO film.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com