Circuit boards, as the core components of electronic devices, carry the important functions of circuit connection and signal transmission, and are widely used in various fields such as communications, computers, industrial control, etc. However, with the rapid development of electronic technology, the design of circuit boards is becoming more and more complex. However, with the rapid development of electronic technology, the design of circuit boards is becoming more and more complex, and the layout of components and lines on them is becoming more and more intensive, which brings great challenges to the inspection of circuit boards.

Traditional circuit board inspection methods, such as visual inspection and simple measuring tools, often struggle to meet the high-precision inspection needs of modern circuit boards. Due to the tiny and dense components and circuits on circuit boards, it is difficult to detect small defects and faults in them with traditional methods. In addition, some problems hidden inside the board are even more difficult to be detected, which may lead to circuit board failures during use and even affect the performance of the entire electronic device.

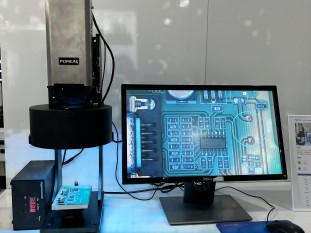

At this time, the large field of view 4K microscope system came into being, become an important tool for circuit board inspection. The system is mainly composed of high-definition color camera, high-magnification lens, multiple ring light source and image processing software and other key devices, they work together to provide strong support for the accurate detection of circuit boards.

1, POMEAS industrial camera: high-definition color camera as the system's “eyes”, able to capture the circuit board surface of the smallest details, and convert them into high-quality digital signals.

2、POMEAS zoom lens: High zoom lens is responsible for providing different magnification observation, so that the user can adjust the field of view and observation accuracy according to need.

3, light source: multiple ring light source for the system to provide uniform, stable lighting conditions, to ensure that the image clarity and contrast to reach the best state.

With the assistance of image processing software, the Big Vision 4K microscope system is able to automate the processing and analysis of captured images, identifying key information such as components, wiring, and solder joints on the circuit boards, and thus detecting potential defects and faults. In addition, the software provides a variety of measurement and comparison functions, making the inspection results more accurate and reliable.

With its excellent performance and advanced device configurations, the Big Vision 4K microscope has significant application advantages in the field of circuit board inspection. It not only solves the problem that traditional inspection methods are difficult to find tiny defects, but also improves inspection efficiency and accuracy, providing strong support for circuit board manufacturing and quality control.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com