Thickness measurement is a crucial technology in the field of precision manufacturing and quality control. With the development of science and technology, white light interference technology has gradually become an important tool for thickness measurement of opaque products. Today for you to explain in detail the principle of white light interference thickness measurement, application and the industry changes it brings.

Introduction to White Light Interference Technology

White light interference is a technique based on the fluctuating nature of light to obtain information about the surface topography of an object by measuring the phase difference of light waves when they are reflected or transmitted at different interfaces. When two or more coherent light waves meet at a certain point in space, if their phase difference is an integer multiple of 2π, light enhancement, i.e., an interference phenomenon, will occur at that point. White light interferometer utilizes this principle, through the white light source emitted multi-color light waves and the surface of the object to be measured reflected or transmitted light waves interaction, the formation of interference fringes, so as to realize the object surface topography of high-precision measurement.

White Light Interferometric Thickness Measurement Principle

In thickness measurement of opaque products, white light interference technology indirectly deduces the thickness of an object by measuring the changes in the interference fringes formed by light reflecting off the surface and inside the object being measured. Specifically, when light strikes the surface of the object to be measured, some of the light is reflected back, while some of the light enters the interior of the object and returns to the surface again after reflecting at an interface. These two beams of reflected light form an interference near the surface of the object, and the distribution and spacing of the interference fringes are directly related to the thickness of the object. By analyzing the changes in the interference fringes, the thickness of the object can be accurately calculated.

Advantages of White Light Interferometric Thickness Measurement

Compared with traditional thickness measurement methods, white light interference thickness measurement has significant advantages. First of all, white light interference technology has a very high measurement accuracy, can reach the nanometer or even sub-nanometer precision, suitable for the occasions of very high precision requirements. Secondly, white light interference measurement speed, can realize real-time online measurement, greatly improving the production efficiency. In addition, white light interference technology also has the characteristics of non-contact measurement, will not cause damage to the measured object, suitable for a variety of materials measurement.

Specific Applications of White Light Interferometric Thickness Measurement

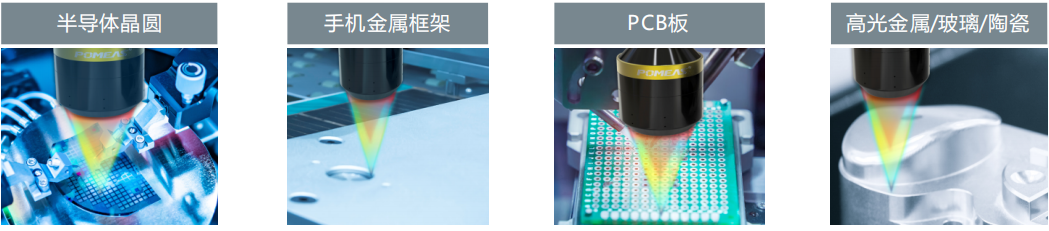

White Light Interferometric Thickness Measurement technology has a wide range of applications in several fields. In the semiconductor industry, it is used to measure the thickness of materials such as silicon wafers and thin films to ensure product quality and performance. In optical component manufacturing, white light interferometric thickness measurement technology is used to detect the thickness and surface topography of optical components such as lenses and mirrors to ensure optical performance. In addition, white light interferometric thickness measurement plays an important role in material science, biomedicine, aerospace and other fields.

With the advancement of technology and the development of manufacturing industry, the requirement of thickness measurement technology is getting higher and higher. The addition of white light interferometric thickness measurement technology to POMEAS Technology's measurement solutions has provided strong support for thickness measurement in a variety of industries with its high accuracy, speed and non-contact nature.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com