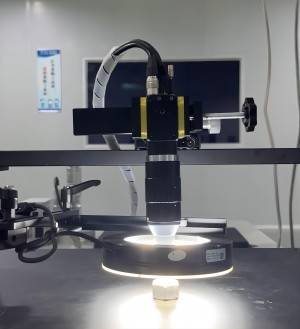

The working principle of the 360° interior lens is mainly based on the optical imaging principle and combines a special optical design and mechanical structure to realize a comprehensive inspection of holes or vessel interiors.

The following is a brief description of its working principle:

1.Optical design: 360° inner wall lens adopts a special optical design, including multiple sets of lenses and optical path design, to ensure that the light can propagate from the bottom to the top of the hole while forming a clear image. This design overcomes the problem that ordinary industrial lenses are unable to photograph vertical interior walls.

2. Mechanical structure: In order to realize 360 ° all-round detection, the lens is usually equipped with a rotating or oscillating mechanism, so that the light can irradiate the inner wall in all directions. At the same time, with precision mechanical transmission and positioning system to ensure the stability and accuracy of the lens.

3. Imaging and Processing: When the light is reflected or refracted through the inner wall of the hole, an image is formed and received by the lens's light-sensitive element. Subsequently, the features and defects of the inner wall are further extracted by image processing algorithms, such as edge detection, noise suppression and image enhancement.

4. Detection and analysis: The acquired images are processed and analyzed by the software system, which can identify various defects, stains, unevenness, etc. of the inner wall. The software system can also compare the holes in different batches or different locations to realize automated detection and quality control.

5. Output and Feedback: Eventually, the inspection results can be output in the form of images, data or reports, which can be provided to the operator or automated control system. Based on the inspection results, potential problems can be detected and corrected in time to ensure the stability and quality of production.

The 360° inner wall lens realizes all-round inspection of the inner wall of holes or containers through its unique optical design and mechanical structure. By combining with image processing and software systems, defects and anomalies in the inner wall can be efficiently detected and analyzed, providing important support for industrial production and quality control.

When taking pictures of the bottom of an object's inner hole and vertical inner wall and other applications, POMEAS 360° inner wall inspection lenses do not need to place the lens inside the hole, and can inspect the inside from the outside, which greatly saves space and cost, and improves the inspection efficiency.

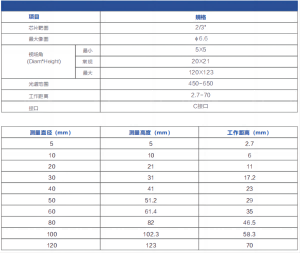

Product Parameters

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION