Image measurement system with its high precision measurement, rapid detection and non-contact measurement and many other advantages, in the industrial manufacturing has shown great application value. It can not only significantly improve production efficiency and ensure high performance of products, but also in the measurement process to avoid damage to the product itself. Therefore, the image measurement system has gradually become an indispensable part of the manufacturing industry. The following are several major reasons why image measurement systems are needed in industrial production:

1, High-precision measurement needs: industrial production, the precision requirements for parts and products are often very high. Image measurement system using high-resolution camera and advanced image processing technology, can realize the small size and complex shape of the high-precision measurement. This helps to ensure that product quality meets design requirements and improve production efficiency.

2, Non-contact measurement advantages: traditional measurement methods often need to contact the object being measured, which may cause damage or deformation. While the image measurement system uses non-contact measurement, by capturing the image of the object to be analyzed, avoiding damage to the measured object, but also reduces the error in the measurement process.

3, Automation and real-time: image measurement system can realize automated measurement, reducing the tediousness and error of manual operation. At the same time, the system is able to work in industrial production environments with high real-time requirements, which improves productivity. This helps enterprises to realize cost reduction and efficiency, and enhance competitiveness.

4, Flexibility and customizability: Different industrial production scenarios and products have different measurement needs. Image measurement system has a high degree of flexibility and customizability, can be customized according to the specific needs of the development, to meet a variety of complex measurement needs.

5, Comprehensive quality control: image measurement system can not only measure the size and shape of the product, but also to assess the surface quality. By detecting surface defects and quantifying the degree of defects, the system can provide comprehensive quality control information to help companies optimize the production process and improve product quality.

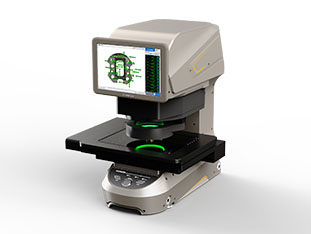

The application of POMEAS image measurement system in industrial production is of great significance to improve product quality, reduce production cost and enhance production efficiency. With the continuous progress of technology and application expansion, image measurement system will play a more important role in industrial production.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com