6.5X zoom lens inspection grinding wheel groove arc application program

Grinding wheels are the most important class of abrasives in grinding processes. The grinding wheel is a porous body made by adding bonding agent to abrasive, through blanking, drying and roasting. Due to the abrasive, binding agent and manufacturing process, the characteristics of the grinding wheel varies greatly, so the processing quality of grinding, productivity has an important impact.

Detecting Difficulties:

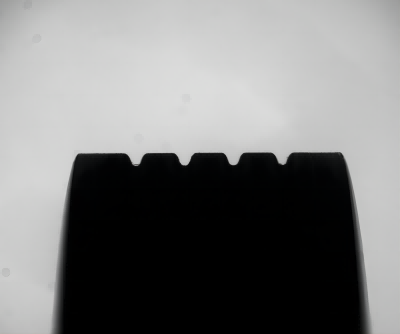

Inspection of grinding wheel grooves is an important part of ensuring their quality and performance. However, in the actual inspection process, there are several difficulties. First, the shape and depth of the grinding wheel grooves are different, which makes the inspection more difficult. Secondly, due to the rough surface of the grinding wheel, it is easy to cause wear and tear on the testing equipment, which affects the testing accuracy. In addition, tiny cracks or defects that may exist in the production process of the grinding wheel also increase the difficulty of detection.

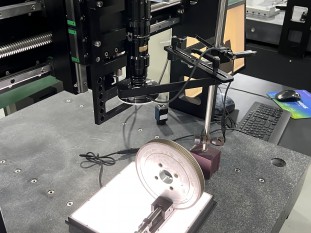

In order to solve the above inspection difficulties, we have developed an application program for 6.5X zoom lens inspection of grinding wheel grooves:

1. Lens using POMEAS 6.5X zoom industrial lens;

2. with eight million high-definition CCD camera;

3. with the POMEAS vision light source and image processing system.

Program Strengths:

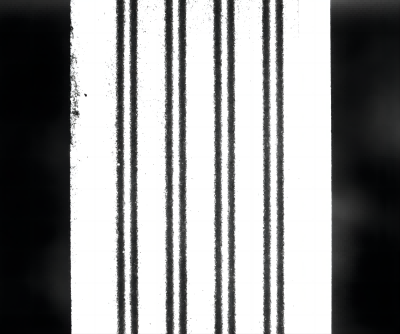

1. High-precision inspection: Through high-definition optics and precise mechanical structure, it is able to realize high-precision inspection of grinding wheel groove arc and accurately capture tiny defects and cracks.

2. Wide range of adaptability: 6.5 times of zoom range makes the program adaptable to different specifications and shapes of grinding wheel groove inspection needs, improving the inspection efficiency and flexibility.

3. Non-contact detection: Avoid the traditional contact detection on the grinding wheel surface wear, while reducing the error and interference in the detection process.

4. Intelligent operation: Combined with advanced image processing technology and algorithms, it can realize automated inspection and data analysis, improving inspection efficiency and accuracy.

Detection case diagram:

With the advantages of high precision, wide range adaptability, non-contact detection and intelligent operation, the vision solution of POMEAS 6.5X zoom lens for detecting the circular arc of grinding wheel groove can effectively solve the difficult problems in the process of inspecting the grinding wheel groove, and improve the production quality and efficiency of the grinding wheel.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION