MetX Multi-Sensor Measurement System for Automotive Engine Components

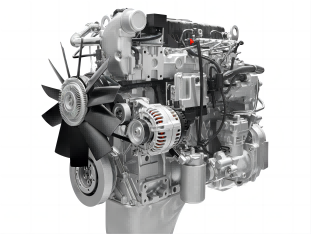

In the process of automobile manufacturing, the accuracy and quality of engine components are crucial to the performance and safety of the entire vehicle. Traditional measurement methods often suffer from insufficient precision and low efficiency, making it difficult to meet the high standard requirements of modern automobile manufacturing. The application of MetX multi-sensor measurement system has revolutionized the measurement of engine parts.

MetX systems are used to measure critical engine components such as crankshafts, pistons and cylinder blocks. By integrating a variety of sensors and measurement modules, the system enables comprehensive inspection of the size, shape and surface quality of these components.

High Accuracy: The MetX system utilizes its high-precision measurement capabilities to accurately capture micron-level dimensional variations in components. Whether it's the diameter of a crankshaft, the height of a piston, or the bore of a cylinder block, the system provides accurate and reliable measurements to ensure that the part meets its design requirements.

High efficiency: The MetX system's high-efficiency measurement capabilities make the entire inspection process faster and more efficient. The multi-station, multi-threaded parallel measurement design significantly reduces measurement time and improves productivity. At the same time, the system's intelligent data management features allow users to easily access measurement data for further analysis and processing.

High degree of integration: The multi-sensing integration capability of MetX system is also fully realized in measuring automotive engines. By integrating different sensors and measurement modules, the system is able to cope with a variety of complex measurement needs and realize comprehensive inspection of components. This flexibility allows the MetX system to be adapted to the measurement of different types and sizes of engine parts, increasing the versatility and applicability of the measurement.

Through the application of the MetX multi-sensor measurement system, the measurement accuracy and efficiency of automotive engine parts have been significantly improved. This not only helps to ensure the performance and quality of the entire vehicle, but also improves productivity and reduces production costs for automakers.

This case is just a microcosm of the many applications of MetX multi-sensor measurement systems in the industrial measurement field. Through continuous technological innovation and product upgrades, MetX systems will continue to provide strong support for the development of the industrial manufacturing field.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION