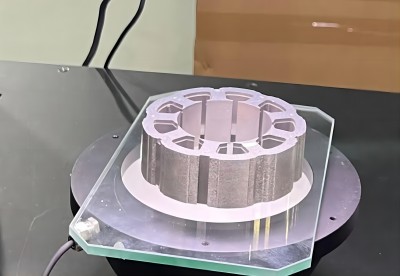

Lens vision solution for inspecting the inner wall of motor cores

Motor cores, as the core component in the motor, carry the important task of increasing the magnetic flux of the inductor coil and achieving the maximum conversion of electromagnetic power. In order to ensure the quality and performance of motor cores, efficient and accurate inspection means are especially important. Based on this, POMEAS developed a 360 industrial lens vision solution for inner wall inspection, in which the industrial camera, light source and 360 lens each play an indispensable role.

Detection difficulties:

1、Complex structure of the inner wall: the inner wall of the motor core often has complex geometry and subtle structural features, which makes it difficult for traditional inspection methods to accurately capture and identify defects.

2、High light conditions: Inner wall inspection requires uniform and stable light conditions to eliminate shadows and reflections and ensure clear images. However, due to the curvature and irregularity of the inner wall, achieving uniform illumination is a technical challenge.

3, limited field of view: Due to the size and structural limitations of the motor core, it is often difficult for conventional lenses to cover the entire field of view of the inner wall, which may lead to the omission or misjudgment of defects.

Inspection programme:

1.Industrial Lens: Lens using Pumice 360° inner wall inspection lens;

2. Industrial Camera: Match with Pumice HD industrial camera;

3. Light source: round light source as the bottom light source to eliminate shadows and reflections, to ensure the clarity and contrast of the image, the ring-shaped upper light source can provide uniform and stable illumination for the inspection area.

The 360 lens is able to complete the inspection of the entire inner wall of the motor core at one angle, without the need to rotate the workpiece several times or use multiple camera lenses, and is able to clearly display all kinds of defects and foreign objects in the inner wall, ensure product quality, and greatly improve the inspection efficiency and accuracy.

Detection effect diagram:

Rendering 1

Rendering 2

This vision solution is widely used in the motor manufacturing industry for inspecting the quality of the inner wall of motor cores. Through the collaborative work of industrial cameras, light sources and 360 lenses, it can achieve all-round, high-precision inspection of the inner wall of motor cores, effectively identifying various defects and foreign objects. In addition, this solution can also be applied to other industrial fields with similar inspection needs, such as automotive parts, electronic products and so on.

With the excellent performance and wide range of applications of the industrial camera, light source and 360 lens, the 360 lens vision solution provides an efficient and accurate solution for the quality inspection of motor cores. As a professional vision solution provider, Promise will provide customers with the best quality solutions to help them achieve business development and innovation.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com