Remote control three-dimensional measurement of the four major difficulties and solutions

In modern measurement technology, multi-sensor measurement systems are widely used in 3D scanning and morphology detection of various objects due to their high accuracy and efficiency. However, there are four major difficulties in the slope 3D scanning for small and complex structured objects such as remote control.

Remote control detection difficulties I: surface shape varies

Remote controls are often irregularly shaped and have a richly detailed surface, which requires a high degree of accuracy and resolution from the scanning system. During the scanning process, it must be ensured that the sensors are able to capture small changes in the surface of the remote control, especially those critical areas that may affect the slope. This requires a scanning system that not only has high resolution, but is also able to work stably at different angles and distances to obtain complete and accurate 3D data.

Remote control testing difficulties II: material with reflective, light-absorbing properties

Due to the variety of materials used for remote controls, the surface may have reflective and light-absorbing properties, which can affect light reflection and reception during the scanning process. How to effectively deal with these surface characteristics to ensure the accuracy and consistency of scanning data.

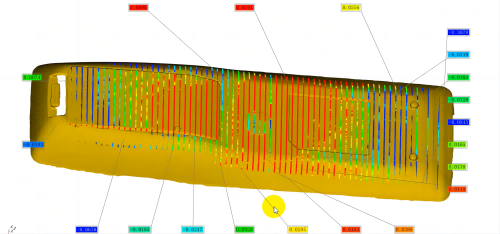

Remote control testing difficulty III: slope measurement

For slope measurement, in addition to the requirement that the scanning system can accurately capture the morphological changes on the surface of the object, the scanning data needs to be processed and analyzed by algorithms to extract the slope information. This involves complex mathematical models and computational processes, requiring engineers to have deep background knowledge of mathematics and physics.

Remote control detection difficulties IV: data comparison

After acquiring the 3D scanning data of the remote control, how to import these data into the analysis system and compare them with the product data is another key link. This requires the establishment of a set of perfect data processing processes, including data format conversion, data cleaning and calibration, and the development of comparison algorithms. Through this process, we can accurately compare the scanned data with the product design data to find out the differences between the two, providing strong support for product improvement and optimization.

In the comparison process, we also need to pay attention to some problems. For example, due to the different scanning environments and operating methods, there may be some errors in the scanning data. Therefore, when comparing the data, we need to take these error factors into full consideration and adopt appropriate algorithms and strategies to correct and compensate.

Multi-sensor measurement systems face many technical difficulties and challenges in measuring the slope 3D scanning of remote controls. However, by continuously optimizing the scanning system and improving the data processing and analysis capabilities, Promise's Multi-sensor Measurement System Metric series can accurately measure and compare the slope of remote controls, providing strong support for product design and improvement.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com