Automotive Triangle Window Curved Glass Inspection Vision Solution

Today's automotive industry development is highly competitive, in order to improve product competitiveness, automobile manufacturers attach great importance to product quality and safety. Automotive glass is an important part of the car, its quality is very important for automotive manufacturing, with the help of advanced technology to carry out quality inspection is not only about the safety of the car, but also the automobile manufacturers to improve the production efficiency of the necessary means.

Automotive triangular window glass size inspection is a very important part of automotive glass quality inspection, triangular window curved glass is a glass product with complex shape and size requirements, its curvature, dimensional accuracy directly affects the safety, comfort and aesthetics of the vehicle. Therefore, it is crucial to strictly test and control the dimensions of automobile triangular window curved glass.

Testing needs and difficulties:

Measure the shape, 3D contour, and other surface dimensions of the curved glass of the triangular window, and compare it with the standard document to evaluate the edge fit and determine whether it meets the assembly requirements.

However, the automotive triangular window glass is a transparent material with strong reflective ability, the traditional measurement methods are prone to interference or distortion, and the edge features are small and complex, the general means of detection can not complete the accurate measurement.

Detection Program:

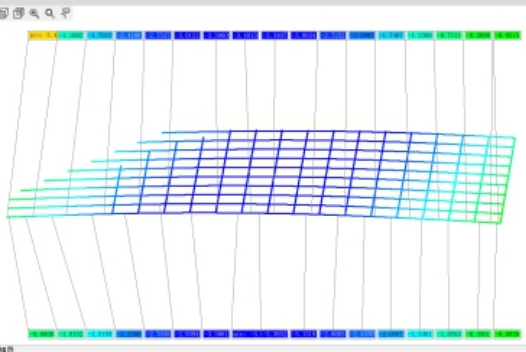

Using POMEAS Spot Spectral Measurement sensors, the automotive triangular window curved glass surface and edges are quickly scanned to obtain the glass dimensions in real time. Combined with POMEAS professional MET X 3D measurement software, the scanning trajectory is determined by the profiling scanning function, and the measurements are quickly captured and output to the 3D contour deviation.

Program Measurement Advantage:

1. High precision: With the high precision measurement capability, POMEAS point spectral sensor can realize the precise measurement of the object, thus ensuring the measurement precision of the contour degree of the curved glass of automobile.

2. High stability: POMEAS point spectral sensor has high measurement stability, no matter what kind of surface material or morphology, it can get consistent measurement results.

3. Wide applicability: POMEAS point spectral sensors are suitable for the measurement of various materials, including metal, ceramics, precision, glass, etc., and have wide applicability in automotive quality measurement.

4. Data visualization: POMEAS point spectral sensor combined with professional measurement software to generate visualization reports, which can clearly present the glass contour chromatogram, and compare the scanning results with the standard documents, which can accurately identify the data differences.

5. Non-contact measurement: POMEAS point spectral sensor adopts non-contact measurement method, which will not cause damage or influence to the measured object, and at the same time, it can also effectively avoid the errors caused by contact measurement.

The POMEAS Point Spectrum Sensor with MET X Measurement Software measurement solution offers a variety of advantages that help to improve the efficiency and accuracy of automotive quality measurements, as well as provide automotive manufacturers with more comprehensive and accurate quality control and R&D support.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com