Flash tester application of motorcycle parts size efficient inspection

The dimensional accuracy of motorcycle parts is important for the overall performance and safety of motorcycles. Through dimensional measurement of motorcycle parts, quality control and production process optimization can be effectively carried out to improve production efficiency and reduce costs.

Motorcycle parts of the dimensional measurement project mainly includes precision parts of the external dimensions, hole diameter hole distance, thickness, angle detection. Flash tester in the motorcycle parts size measurement has significant advantages, mainly reflected in the following aspects:

1. The flash tester adopts non-contact measurement method, which will not cause any damage to the body of the motorcycle parts and effectively protect the measured object.

2. The flash tester can measure 99+ dimensional features at a time, and the carrier table can complete multiple dimensional inspections for multiple products at a time.

3. The flash tester has the functions of auto-focus, intelligent edge recognition, etc., the measurement is accurate and the result will not vary from person to person.

4. The measurement process is simple and easy to understand, after placing a key to measure, easy to get started.

5. Measurement results are automatically displayed and support output saving, easy to extract and view at any time.

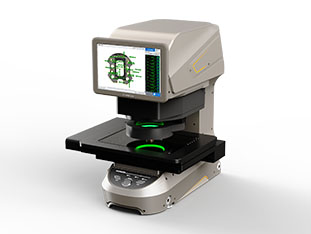

By using the POMEAS IMAGE flash tester to measure motorcycle parts, not only does it improve measurement efficiency, but it also reduces the risk of human error, further improves product quality, and facilitates the monitoring and management of the production process.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION