For what industries are Metric multi-sensor measurement systems suited to the measurement needs of?

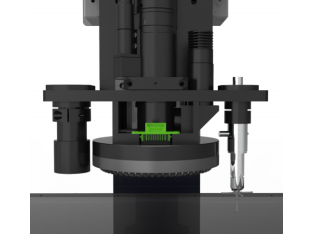

Metric multi-sensor measurement systems are used in a wide range of applications to quickly and accurately measure parts of all shapes and sizes, providing a wealth of measurement data and analytical capabilities to support product quality improvement and productivity enhancement.

The following are examples of industry applications:

Manufacturing: In the manufacturing industry, Metric multi-sensor measurement systems can be used to dimension metal parts to ensure they meet design specifications. For example, it can measure parameters such as bore diameter, length, width, thickness, and contour, and can handle large quantities of parts in a short period of time, increasing productivity.

Electronics and semiconductor industry: In the electronics and semiconductor industry, the Metric multi-sensor measurement system can be used to inspect tiny-sized components such as integrated circuits and chips. It measures the size, shape and position of components with high accuracy to ensure component quality and reliability.

Watch and Precision Instrument Manufacturing: In the watch and precision instrument manufacturing industry, Metric multi-sensor measurement systems can be used to inspect the size and shape of various components and assemblies. For example, it can measure the size and shape of components such as gears, bearings, and rails to ensure the accuracy and stability of a clock or precision instrument.

Automotive: In the automotive industry, the Metric multi-sensor measurement system can be used to inspect the size and shape of automotive components. For example, it can measure the size and shape of engine, chassis, body and other components to ensure the quality and safety of automobiles.

Aerospace: In the aerospace industry, Metric multi-sensor measurement systems can be used to inspect the size and shape of aircraft components. For example, it can measure the size and shape of components such as wings, fuselage, engines, etc. to ensure the safety and stability of an airplane.

The application of Metric multi-sensor measurement systems can significantly improve measurement accuracy and productivity, reduce human error, and ensure the stability and reliability of product quality.

In addition, Metric multi-sensor measurement system can also realize automated measurement, reduce manual intervention, improve production efficiency and reduce production costs. With the continuous progress of science and technology and the continuous improvement of application requirements, the application prospect of Metric multi-sensor measurement system will be more broad.

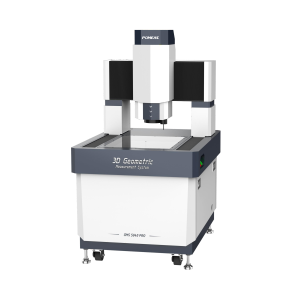

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION