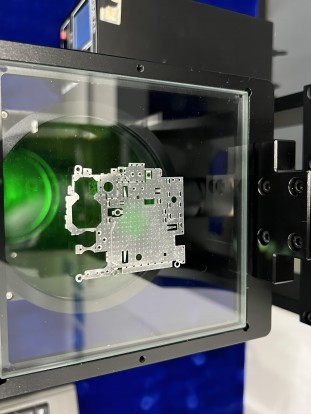

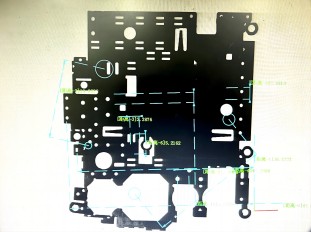

High-resolution telecentric lens to measure dimensions of metal parts

High-resolution telecentric lens is a specially designed optical lens with high resolution, low aberration and telecentric imaging, which is widely used in industrial inspection, machine vision and precision measurement. It can have five advantages such as parallax-free measurement when measuring metal parts as follows:

1, high-precision measurement: high-resolution telecentric lens can provide high-precision images, thus realizing high-precision measurement of the size of metal parts. It can reduce the measurement errors caused by lens distortion and viewing angle errors and improve the accuracy of measurement.

2, parallax-free measurement: the design of the telecentric lens makes it possible to realize parallax-free measurement within a certain working distance. This means that no matter how the position of the measured object changes, the measurement results will not be affected by changes in the angle of view, thus ensuring the consistency and reliability of the measurement.

3, high resolution: high-resolution telecentric lens with high resolution, can capture the details and minute features of metal parts. This is very helpful for measuring small-sized metal parts or applications that require analysis of details.

4, strong anti-interference ability: telecentric lens can effectively reduce the interference caused by ambient light and reflection, improve the quality of the image and the stability of the measurement. This is very important for measurement in industrial environments.

5, fast measurement: high-resolution telecentric lens usually has a high frame rate, can achieve rapid measurement and data acquisition. This helps to improve productivity and automation.

When using high-resolution telecentric lenses for dimensional measurement of metal parts, it is also necessary to combine them with appropriate measurement software and algorithms for accurate dimensional measurement and analysis. And for special measurement needs, it may be necessary to select telecentric lenses with specific functions and features, such as large magnification ratios, long working distances or special optical designs.

Starting from producing optical lenses and measuring microscopes, POMEAS Technology has gradually formed two core technology platforms, namely, volume inspection software and imaging optoelectronics, and has been deeply cultivating in the field of machine vision and optical measurement for more than 20 years, always focusing on the field of machine vision, and adhering to the road of craftsmanship, providing practical, high-precision, and high-efficiency industrial inspection solutions for users in different industries with dedication and professionalism.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com