Plastic parts are widely used in modern manufacturing. From automotive components to electronic device housings, plastic parts play an important role in a variety of fields. However, in order to ensure the quality and functionality of plastic parts, it is crucial to perform 3D profile inspection on them.

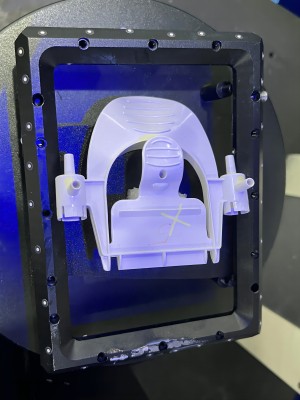

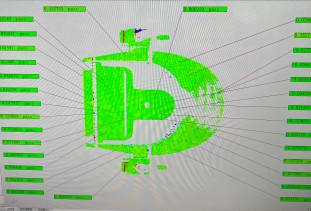

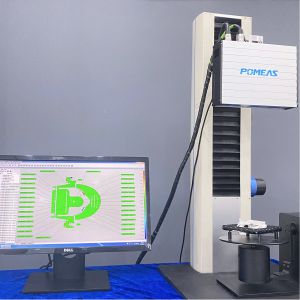

3D contour inspection is an advanced technology to accurately measure and analyze the shape, size and surface features of plastic parts. By using 3D measuring equipment, structured light scanners, we can acquire 3D point cloud data of plastic parts. This data can be used to assess the plastic part's geometry, dimensional accuracy, surface roughness, and conformance to design specifications.

3D profile inspection is important for the production process of plastic parts. First of all, it can help manufacturers to ensure the quality and consistency of their products. By inspecting the 3D profile of plastic parts, we can detect potential defects and deviations such as dimensional errors, deformation, cracks, etc. at an early stage. This helps to take timely corrective measures to avoid unqualified products entering the market and improve customer satisfaction.

3D contour inspection can improve productivity. By quickly and accurately evaluating the contour of plastic parts, manufacturers can reduce scrap rates and lower the cost of rework and reworking. In addition, inspection data can be used to optimize production processes and improve mold design, resulting in increased productivity and product quality.

3D profile inspection can also support product development and design improvement. By analyzing inspection data, engineers can gain insight into the geometric characteristics and performance of plastic parts, identifying potential problems and room for optimization. This helps to continuously improve product design and increase product functionality and reliability.

3D profile inspection is an integral part of the production process for plastic parts. It provides a precise means of measurement and analysis to help manufacturers ensure product quality, improve production efficiency, and support product development and design improvement. As technology continues to advance, 3D profile inspection will play an increasingly important role in plastic parts manufacturing.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION