Laser image autofocus microscopy system for inspection of electronic parts

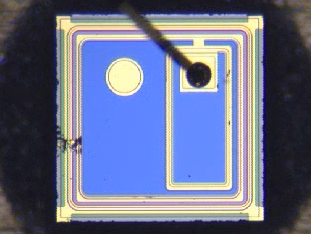

With the rapid development of science and technology, electronic parts are more and more widely used in various industries, and their precision and performance requirements are also higher and higher. Therefore, the inspection and quality control of electronic parts are particularly important. As a high-precision and high-efficiency inspection means, laser image autofocus microscope system is gradually emerging in the field of electronic parts inspection.

The laser image autofocus microscope system mainly consists of an objective focusing motion module, an objective mounting module, a microscope tube module, a laser sensor module, and an APO objective module. These modules work in tandem to ensure that the system is capable of realizing high-precision inspection of electronic parts.

① The Objective Lens Focusing Motion Module is responsible for controlling the up and down movement of the objective lens to realize the auto-focusing function. It automatically adjusts the distance between the objective lens and the sample according to the position change of the surface of the electronic parts to ensure that the laser beam is always focused on the sample surface.

② The objective lens mounting module is used to fix and support the objective lens to ensure its stability during the inspection process. It has a solid structure design and allows easy replacement of the objective lens to meet different inspection needs.

③ The Microscope Tube Module connects the objective lens to the Laser Sensor Module and ensures that the laser beam is transmitted between the objective lens and the sample in a non-destructive manner. It is made of highly transmissive material, providing a reliable guarantee for acquiring clear images.

④ The laser sensor module is responsible for receiving the laser beam that has been focused by the objective lens and converting it into an electrical signal. It is characterized by high sensitivity and high resolution, and can accurately capture minute details and defects on the surface of electronic parts.

⑤ The APO objective module adopts advanced APO (complex achromatic aberration) technology, which eliminates aberrations such as chromatic and spherical aberrations to obtain clearer and sharper images. At the same time, the module is also equipped with an objective lens replacement function, which allows users to easily replace objective lenses of different magnifications or types according to different inspection needs, in order to adapt to different sizes of electronic parts and inspection accuracy requirements.

Laser image autofocus microscope system is widely used in electronic parts inspection. It can be used to observe the surface morphology, microstructure and defects of electronic parts, providing an important basis for quality control. At the same time, the system can also be used to measure the dimensional and positional accuracy of electronic parts, providing key data for quality control in the production process.

The laser image autofocus microscope system provides an efficient and accurate solution for electronic parts inspection through its unique composition and functions. With the continuous progress and improvement of the technology, it is believed that the system will play an even more important role in the future, providing a strong guarantee for the quality control of electronic parts.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com