Vision solution for pre-welded seam detection in blade battery positive electrode in-casing machine

With the rapid development of the new energy market, the continuous innovation and improvement of battery technology is particularly important. Among them, blade batteries, as a new type of battery technology with higher energy density and longer service life, have attracted much attention.

In the production process of blade battery, when installing the top cover, the pole lugs will be bent, and the positive pole lugs are hard, which may cause damage to the pole lugs, so real-time inspection is needed. As a solution provider of machine vision sensors and solutions, POMEAS can use 2D+3D solution to realize efficient and accurate detection of the pre-welded seam of the blade battery positive electrode into the casing machine.

Detection Program:

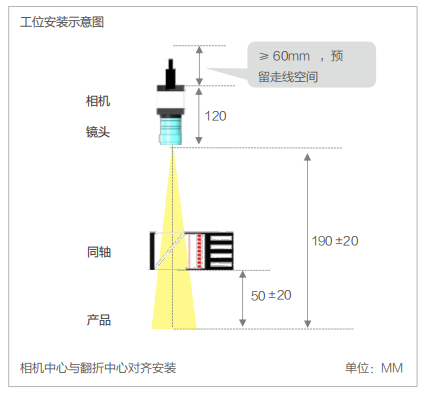

Workstation 1: 2D vision solution with real-time video recording

Configuration options:

◆ Camera: POMEAS five million black and white CCD camera VP-CCN-050G15BSC

◆ Lens: POMEAS five megapixel 16mm fixed focal length FA lens VP-LEH-1616M.

◆ Light source: POMEAS white coaxial light source.

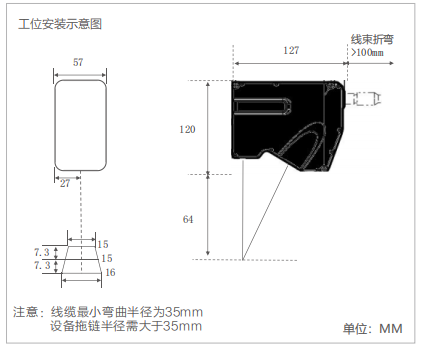

Workstation 2: 3D inspection program to complete pre-welded seam inspection

Configuration Selection:

◆ The use of the POMEAS line laser displacement sensor, fast and accurate completion of the weld seam inspection.

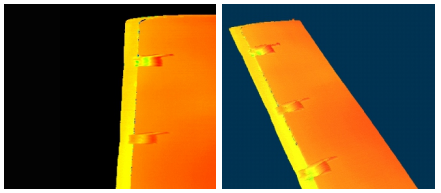

Detection effect diagram:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION