Appearance inspection of automotive battery top cover peripheral welding is an important means to ensure welding quality and safety. By inspecting the appearance, welding defects can be detected in time to prevent these problems from affecting the sealing and safety of the battery.

Detection needs:

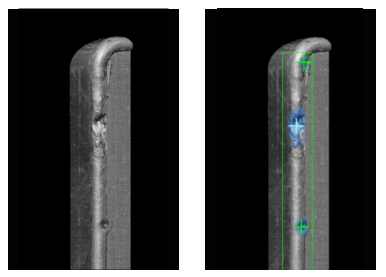

Inspect the appearance of the perimeter weld to identify the presence of defects such as pops and pits.

Detection Methods:

◆ Gray-scale highlighting of height mutation information in height images using a POMEAS line laser displacement sensor to bring out raised or pitted areas;

◆ Defect marking of the grayscale emphasis map, analysis of the relevant area, height and other characteristics of the marking information, screening out defective areas that meet the judgment specifications。

Detection method:

◆ Extraction of the cross-section profile at the weld track;

◆ Search for the highest point at the weld trajectory;

◆ Fit a straight line to the platform position datum on the inside of the contour;

◆ Calculate the distance from the highest point to this reference line as the weld flanging amount;

Detection accuracy:

◆ Repeatability: 0.01mm (laboratory test, linear motor + marble platform, the actual accuracy of the field test shall prevail)。

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION