Pilot line top cover welding machine post-weld 3D inspection program

Post-weld inspection of the pilot line top cover welding machine refers to the inspection of the welding quality after the pilot line top cover welding machine finishes welding, mainly for the appearance. This kind of inspection is an important link to ensure the welding quality and product reliability, and is also a necessary means to improve production efficiency and maintain good equipment condition.

Detection needs:

Able to burst point (diameter ≥ 0.2mm), broken welding, false welding, off-set, pits, trachoma, air holes, bumps burrs, weld slag, pinholes and other defective products to pick out the accuracy of the detection system ≤ ± 0.02mm.

Detection Program:

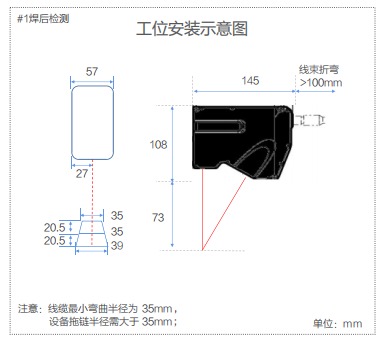

Using POMEAS line laser displacement sensor, the sensor is hung on top of the XR axis, the product is transported to the set detection position by the Y axis; after the cylinder lifts the product in place, the PLC gives the scanning instruction, the product is moved, the sensor is fixed, and after the scanning is completed, the sensor is moved to the B channel to continue to process the other 1PCS product.

Installation schematic:

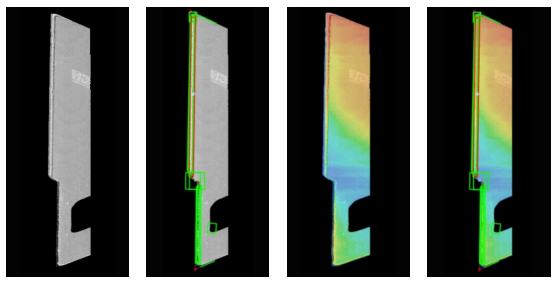

Detection effect diagram:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION