The development of machine vision industry has become an integral part of modern industrial production. Visual inspection plays an important role as one of the core technologies of machine vision. Machine vision system uses optical imaging devices to obtain image information of target objects, and then analyzes and identifies the images through image processing and pattern recognition technology, so as to realize quality inspection, classification, positioning and other functions in automated production lines. The accuracy, reliability and stability of vision inspection are important for improving product quality, production efficiency and reducing costs.

Line scan industrial lens is one of the very important components in machine vision system, which plays a vital role in vision inspection. Line scan lens can obtain the information on the surface or inside of the object, with high resolution, high sensitivity, high transmittance and other characteristics, which can provide high-quality image information, and provide the basic data for the subsequent image processing and analysis. At the same time, the scanning speed of the line scanning lens is very fast, to meet the real-time inspection needs of high-speed production lines.

Line scan lenses have the following applications in the machine vision industry:

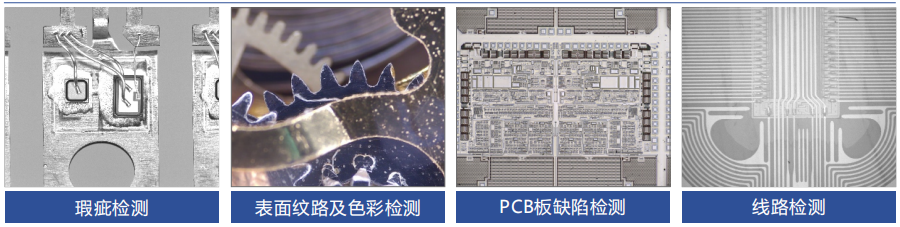

1. Defect detection: Line scanning lens can be used for defect detection on production lines. By scanning the product surface, obtaining its image information and analyzing it, it can quickly and accurately detect whether there are scratches, dents, impurities and other defects on the product surface. It helps to improve product quality and reduce the rate of defective products.

2. Surface texture and color analysis: The line scanning lens can be used to analyze the texture, color and other information on the surface of the object. By identifying and analyzing the shape, size and arrangement of the surface texture, it can determine the material, structure and other characteristics of the object; by analyzing the surface color, it can realize the color classification and screening of products and other functions.

3. Line identification: By scanning the wires, cables and other target objects on the production line, we can obtain their image information and analyze it, so as to realize the automatic identification and tracking of the line and other functions. This helps to improve production efficiency, reduce costs and ensure production safety.

Line scan industrial lenses have a wide range of application prospects in the machine vision industry. With the continuous development of technology, the performance and functions of line scan industrial lenses will be continuously improved and perfected, bringing more innovation and development space for the machine vision industry.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com