How to complete the 3C industry dimensional inspection with flash tester?

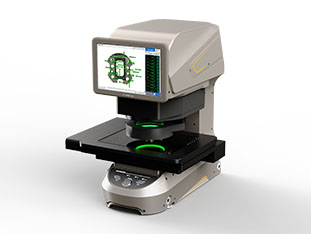

In the 3C industry, the dimensional accuracy of parts directly affects the performance and quality of products. If the dimensions of the parts are inaccurate, it may lead to assembly difficulties, shorter service life and other problems. Therefore, conducting strict dimensional inspection is a key part of ensuring product quality. As a non-contact measuring device, flash tester can quickly and accurately detect the dimensions of parts to improve production efficiency and product quality.

Measurement process:

1. Place the 3C part to be measured on the flash tester carrier table and ensure that it is placed smoothly;

2. Position the part through the flash tester software and program the required measurement parameters and set the tolerance values;

3. Press the start button, flash tester using the built-in image processing algorithms on the part image data processing and analysis, to calculate the product size;

4. Flash tester to produce a measurement report, automatically determine whether qualified or not, the measurement results are shown on the right side of the display for users to view and record.

Scenarios for the application of flash meters in the dimensional measurement of 3C parts:

1. Mobile phone parts size measurement: There are many types of cell phone parts with high dimensional accuracy requirements. Flash tester can help manufacturers achieve efficient quality control of cell phone parts through high-precision measurement and error analysis.

2. Dimensional measurement of computer parts: Computer parts require high manufacturing accuracy and high precision dimensional inspection equipment. The flash meter can quickly and accurately detect the dimensions of computer parts through non-contact measurement.

3. Camera module size measurement: camera module is one of the key components of the smart phone, its dimensional accuracy directly affects the optical performance of the camera and image quality. Flash meter can realize the camera module length, width, height, radian, segment difference and other dimensional detection.

Flash testers can also be used for dimensional inspection of circuit boards, battery packs and other core components of electronic products. With the advantages of high efficiency and high accuracy, flash testers can also be widely used in automotive manufacturing, aerospace and other fields.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION