Laser autofocus microscope -- capturing microscopic moments with fast focusing

In the exploration of the microscopic world, every subtle change and moment may contain important information. In order to be able to observe and study these microscopic phenomena clearly and accurately, advanced microscopy techniques are essential. POMEAS laser autofocus microscopes stand out for their excellent and extremely fast focusing capabilities, providing a powerful tool for microscopic research in industry and other fields, allowing us to capture those fleeting microscopic moments with ease.

Principle of Extreme Focus Technology

The POMEAS laser autofocus microscope system utilizes advanced laser detection technology and a high-speed feedback control system. By firing a laser beam of a specific wavelength onto the sample, a sensor is then utilized to detect changes in the intensity and phase of the reflected or scattered light. When the distance between the sample and the lens changes, the characteristics of these light signals also change. The high-speed feedback control system in the system is able to analyze the changes in these light signals in real time and quickly adjust the position of the lens to achieve fast and accurate focusing. This laser-based detection and feedback mechanism enables a very high level of focusing speed, enabling focusing operations to be completed in a very short period of time, ensuring that no critical microscopic moments are missed!

Application Areas:

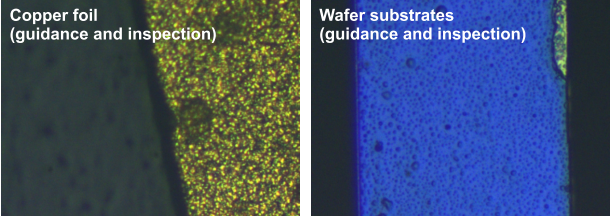

1、Semiconductor Inspection: In the manufacturing process of semiconductor chips, the microstructure and defect detection of the chip is highly required. POMEAS laser autofocus microscope system's very fast focusing function can quickly focus scanning on different areas of the chip, and timely discover tiny defects in the chip, such as line short circuit, broken circuit, scratches on the chip surface, and so on. This helps to improve the production quality and yield of the chip and reduce the production cost. For example, in the photolithography process of the chip, it can quickly focus on the photolithography pattern to detect the photolithography accuracy and defects to ensure the performance and reliability of the chip.

2、Precision Manufacturing Inspection: For the manufacture of precision mechanical parts, optical components, etc., it is necessary to strictly inspect their microscopic dimensions and surface quality. The system's very fast focus function can focus on different parts of the parts in a short time to measure and improve the detection efficiency. At the same time, its high-resolution imaging capability can clearly display the microscopic details of the parts, such as surface roughness, tiny cracks, etc., providing a reliable means of quality control for precision manufacturing.

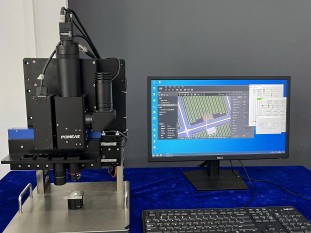

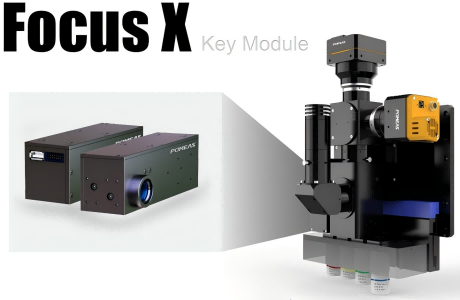

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com