Background and Difficulties of Cell Phone Backplane Profile Inspection

With the rapid development of the smartphone industry, the appearance quality and precision of cell phone backplanes are increasingly required. As an important part of the cell phone, the precision and consistency of the contour of the cell phone backplane directly affects the overall appearance and performance of the cell phone. Therefore, it is particularly important to detect the contour of cell phone backplane. However, cell phone backplane contour detection faces many difficulties:

1、The appearance of cell phone backplane has many kinds of defects, including bumps, scratches, hairs, foreign objects, dirt, bright spots, etc. These defects are small in size and difficult to detect.

2、The materials and shapes of cell phone backplanes are different, which puts forward higher requirements on the adaptability and precision of inspection equipment.

3、During the inspection process, it is necessary to ensure that no damage is caused to the back plate of the cell phone, and at the same time, improve the inspection efficiency and accuracy.

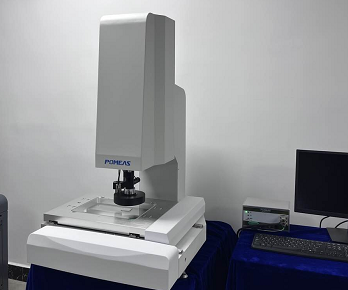

Cell phone backplane contour scanning solution: 3D contour scanner

POMEAS 3D contour scanner is suitable for height, segment difference, flatness and other dimensional inspection, which is very suitable for the industry inspection with high precision requirements. By scanning the back plate of a cell phone, the 3D contour scanner can obtain its 3D data and compare it with the standard file to determine whether the contour of the cell phone back plate is up to the standard or not.

POMEAS Spectral Confocal Sensor

POMEAS Spectral Confocal Sensors are the preferred solution for a wide range of industries due to their high accuracy and non-contact measurement. The sensor is able to measure accurately from a close distance without directly touching the object being measured, effectively avoiding wear and tear or contamination due to contact. In cell phone backplane profile inspection, POMEAS spectral confocal sensors can measure height, thickness and other key parameters to ensure the accuracy and consistency of cell phone backplanes.

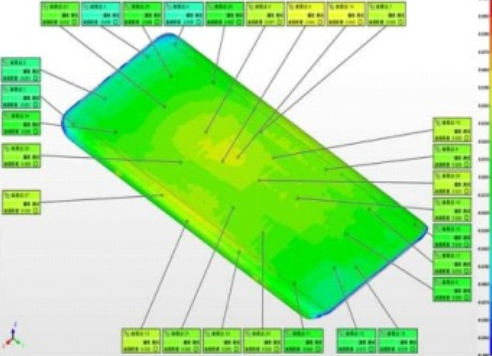

Scan of cell phone backplane profile shown

Program Advantages

(1) High precision: Both the 3D profile scanner and POMEAS spectral confocal sensor are capable of high-precision measurement, which can meet the high-precision requirements of cell phone backplane profile inspection.

(2) Non-contact Measurement: Both devices adopt non-contact measurement method, which avoids the damage or contamination problems that may exist in traditional measurement methods.

(3) Comprehensive inspection: The program can measure the height, segment difference, thickness, flatness, contour and other parameters of the cell phone backplane, ensuring comprehensive inspection of the cell phone backplane.

(4) High efficiency: The 3D profile scanner and POMEAS spectral confocal sensor are both equipped with fast measurement capability, which can complete the inspection of the cell phone backplane in a very short time and improve the inspection efficiency.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com