Terminal width measurement is an important part of ensuring the quality and safety of electrical connections, and choosing the right measurement equipment is critical to ensuring accuracy and efficiency. Below are the requirements for terminal width measurement and recommended measurement solutions:

Terminal Width Measurement Requirements

Terminal width measurement needs to meet the requirements of high precision and high efficiency, while the measurement equipment should have stability and reliability to ensure the accuracy and consistency of the measurement results. In addition, the measurement equipment should be easy to operate and easy to maintain, in order to facilitate the use and management of the production site.

Measurement program

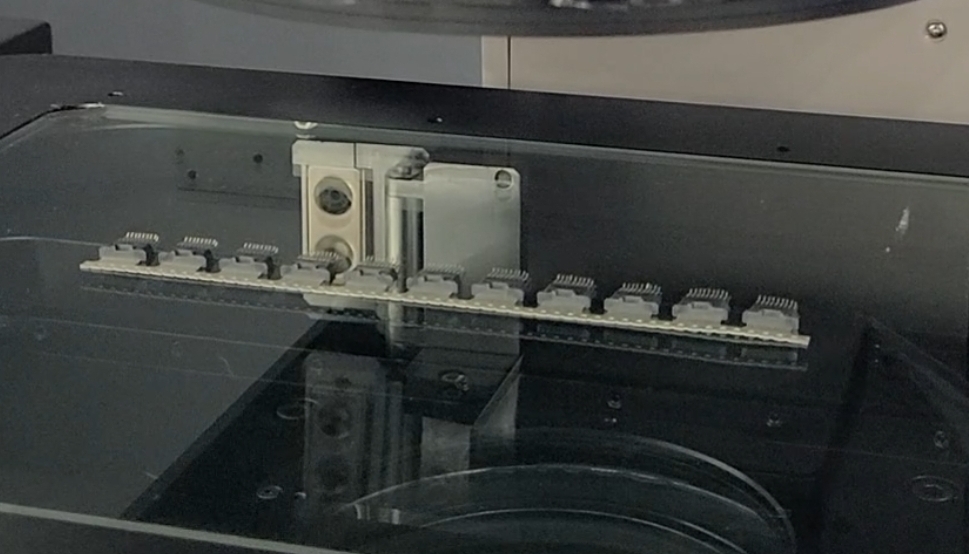

In-Line Image Dimension Measuring Instrument HM Series

In-line Image Dimension Measuring Instrument HM series is a high-precision and high-efficiency measuring equipment for various terminal width measurements. With telecentric lens and intelligent image analysis system, this equipment can accurately capture product images and realize fast and efficient batch measurement. Its measurement accuracy can reach micron level, which meets the manufacturer's requirements for inspection accuracy. At the same time, the device is easy and convenient to operate and has a wide measurement range, which is suitable for various production sites.

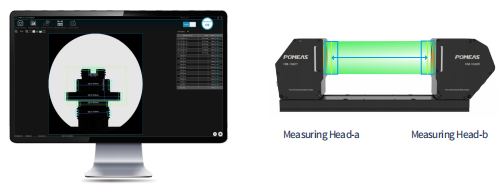

Flash Meter Image3 Series

The flash tester Image3 series is a measuring device based on machine vision technology and is suitable for quick measurement of dimensions such as terminal width. Through the principle of one-button flash measurement, the device can quickly capture product images and carry out measurements, which greatly improves the measurement efficiency. At the same time, the device has high accuracy and stability, which can meet the requirements of the production site for measurement accuracy and efficiency. In addition, POMEAS flash meter is easy to operate and easy to maintain, which is convenient for the use and management of the production site.

Vision Measurement Solutions

Vision Measurement Solution is a customized measurement solution based on machine vision technology for scenarios with specific requirements for dimensions such as terminal width. The solution can be customized according to the actual needs of the measurement equipment and the measurement process, to achieve high precision and high efficiency measurement. A vision measurement solution usually includes components such as cameras, lenses, light sources and image processing software, which can be selected and configured according to different measurement needs. Through customized vision measurement solutions, accurate measurement and real-time monitoring of terminal width can be achieved, improving production efficiency and product quality.

For the requirements of terminal width measurement, you can choose measurement equipment such as POMEAS in-line image dimension meter, POMEAS flash meter or vision measurement solution. These devices have the advantages of high precision, high efficiency, stability and ease of operation, which can meet the requirements for measurement accuracy and efficiency at the production site. When choosing measurement equipment, comprehensive consideration and selection should be made according to the actual needs.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com