A quick look at the practical applications of laser dimensional gauges

In today's highly sophisticated and automated industrial production and quality inspection, the requirements for dimensional measurement of various objects are becoming more and more stringent. POMEAS laser dimensional measuring instruments are like a bright star, bringing precise and efficient solutions to many complex dimensional measurement problems.

POMEAS laser dimensional gauges have demonstrated outstanding performance in industrial applications, and their ability to perform high-precision inspections on-line has made them an important part of the production process. When faced with the challenge of height measurement, whether it is the slightest difference in height of a tiny component or the height parameter of a large structure, it is possible to measure it with extremely high precision.

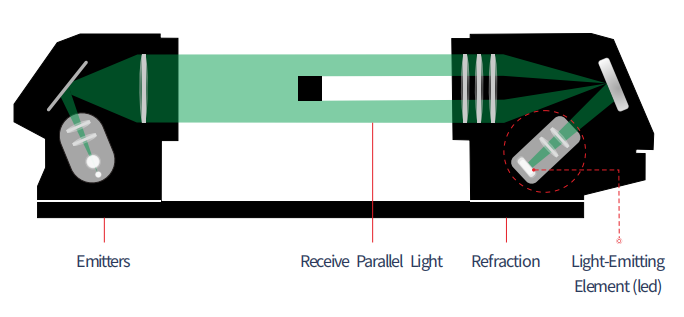

Laser Dimension Gauge Principle

Through advanced laser technology, it can accurately capture the dimensional information of an object in the vertical direction, avoiding the human error and lack of precision that may occur in traditional measurement methods. For example, in the manufacturing process of electronic chips, the measurement of the height of the tiny structures inside the chip has a crucial impact on the performance of the chip, and POMEAS laser dimensional measuring instruments can easily perform this job, ensuring that every chip meets the strict height standards.

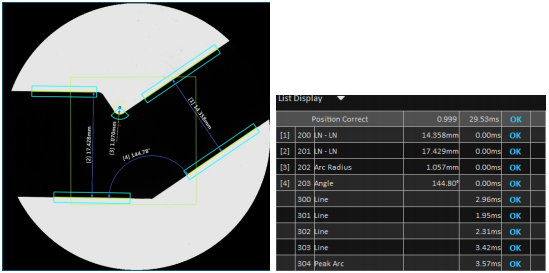

Inside and outside diameter measurements are critical for objects with annular structures, such as bearings and fittings in machine parts. POMEAS laser dimensioning systems can quickly and accurately measure the inner and outer diameters of these objects to a very high level of accuracy. In automotive engine production, the inner and outer diameter dimensions of piston rings need to be tightly controlled to ensure sealing and movement between the piston and cylinder wall. The gauge can measure the inner and outer diameters of piston rings in real time on the production line, and in case of deviation, an alarm will be issued immediately to avoid unqualified products from going to the next process.

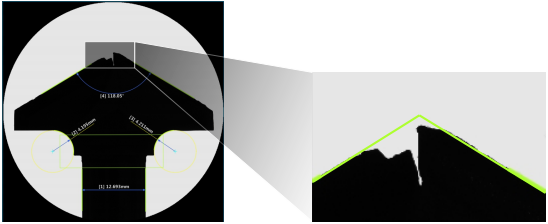

The POMEAS laser dimensioning system can also handle complex shapes. It can scan the contour of the object with high precision, obtain the 3D shape information of the object and compare it with the design model. In fields such as mold making and sculpture reproduction, accurate shape measurement ensures a high degree of consistency between the product and the design prototype. Whether it is an automotive mold with complex curved surfaces or the reproduction of an artistic sculpture, this measuring instrument can play to its unique advantage and provide accurate data support for production and creation.

POMEAS Laser Dimension Measuring Instruments have become an indispensable tool for industrial production and quality inspection with their excellent ability to detect height, internal and external diameters, shapes and other difficult problems with high accuracy on-line, promoting the development of various industries in the direction of higher quality and refinement.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com