In the hardware machining industry, it is vital to ensure the accuracy of workpiece dimensions, which relies on the right dimensional measuring equipment. Currently, there is a wide range of hardware workpiece sizing equipment available, here are a few common types:

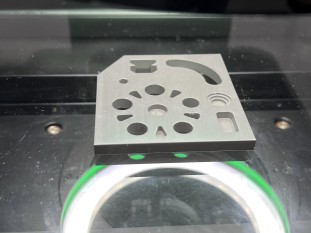

Flashing Measuring Instrument

The flash tester is an efficient measuring device. It makes use of advanced optical imaging technology and can complete the measurement of hardware workpieces in a short time. It is characterised by its extremely fast measuring speed, and for some complex shapes of hardware workpieces, multiple dimensions can be obtained at once. For example, for hardware connectors with multiple holes and complex contours, the flash tester is able to quickly capture the features and give accurate dimensional information. This ability to measure quickly greatly improves production efficiency and is particularly suitable for sampling or full inspection of hardware workpieces in mass production.

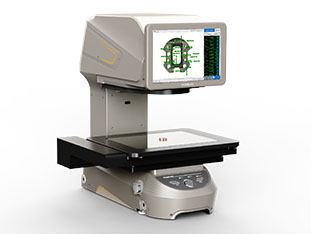

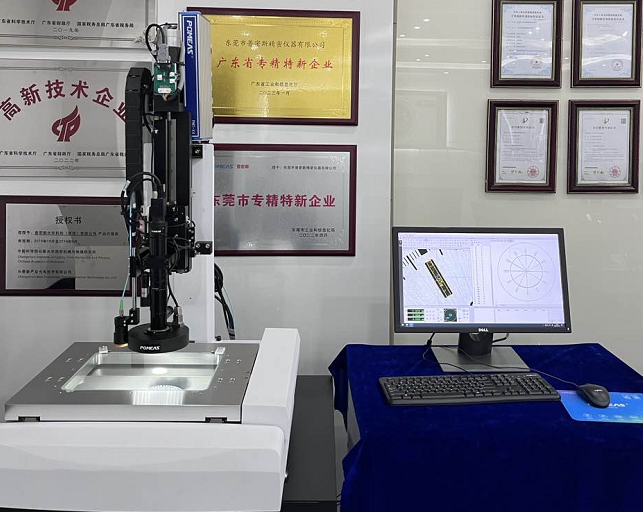

Image Measuring Instrument

The Image Measuring Instrument images the hardware workpieces through the optical lens and combines the software algorithm to analyse and measure the dimensions of the workpieces. It can provide high-precision measurement results, and can accurately measure the length, width, height, diameter and other dimensional parameters of some micro-sized hardware workpieces, such as small screws and precision hardware fittings. The Image Measuring Instrument also has a magnification function, which can clearly present the details of the workpiece, help the operator to determine the measuring point more accurately and ensure the measuring accuracy, which is the ideal choice for the measurement of workpieces with high accuracy requirements in hardware processing.

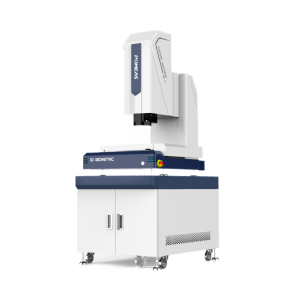

Online Projection Image Measurement

The in-line projected image measuring machine also offers unique advantages in the dimensional measurement of hardware workpieces. It allows real-time measurement of hardware parts directly on the production line. When the hardware workpiece passes through the measuring instrument on the assembly line, its projected image is captured and analysed quickly. This real-time on-line measurement can detect the deviation of workpiece dimensions in time, which facilitates timely adjustment of the production process and reduces the scrap rate. Moreover, it can be adapted to different types of hardware workpieces, whether they are simple block workpieces or workpieces with a certain shape complexity, all of them can be measured effectively.

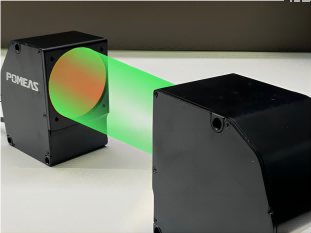

Visual Inspection Solutions

A vision inspection solution is a comprehensive measurement tool. It usually consists of several vision sensors, image processing software and related control system. By arranging the visual sensors at different angles, the image information of the hardware workpiece can be comprehensively acquired. These images are then analysed using complex image processing algorithms to achieve accurate measurement of the dimensions of the hardware workpiece. The vision inspection solution is highly flexible and customisable, and can be customised according to the shape and size range of different hardware workpieces and the requirements of the production environment, and is widely used in the automated production line of various hardware workpieces.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com