In modern industrial production, product quality inspection is a crucial part of the process. In order to ensure flawless product appearance and legible characters, POMEAS has introduced an advanced 360° exterior lens to provide companies with an efficient and accurate inspection solution.

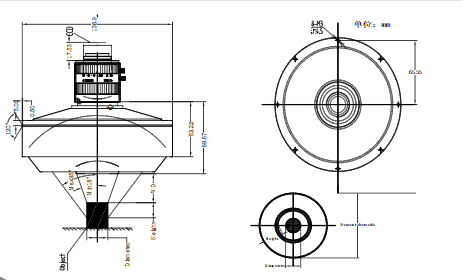

How the 360° exterior lens works

The 360° exterior lens uses a unique optical design and advanced imaging technology to inspect the full range of product appearance. Its working principle mainly includes the following aspects:

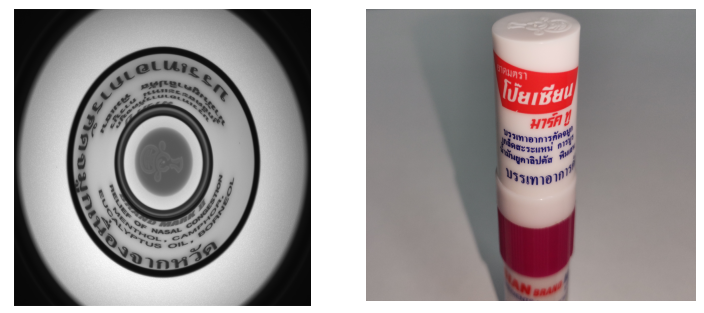

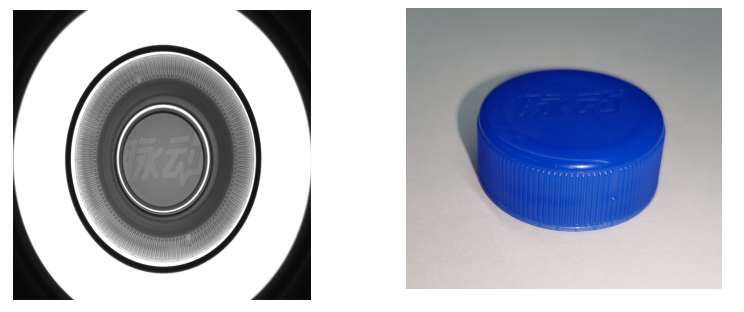

1. multi-view imaging: 360 ° exterior wall lens is usually composed of multiple optical elements, can be shot from different angles of the product. These optical elements work together to capture the image information of the product in all directions, to ensure that there is no dead angle detection. For example, when detecting a round battery, the lens can simultaneously acquire images from multiple angles, such as the front, side, top and bottom of the battery, so as to get a comprehensive understanding of the battery's appearance.

2. Image stitching and fusion: Since the 360° exterior wall lens captures the product from multiple angles, these images need to be stitched and fused to form a complete 360° panoramic image. POMEAS exterior wall lenses use advanced image algorithms to quickly and accurately stitch multiple images into a seamless panoramic image. During the image stitching process, the algorithm automatically adjusts the brightness, contrast and colour of the image to ensure consistent quality of the stitched image.

3. Defect Identification and Character Detection: Once a complete 360° panoramic image has been created, POMEAS' inspection system uses advanced image processing techniques to analyse the image. By extracting and analysing the pixel information in the image, it is possible to detect all kinds of defects on the product surface, such as scratches, pits and stains. At the same time, the system can also detect the characters on the product surface to ensure the clarity and accuracy of the characters. For example, in the inspection of medicine bottles, the system can detect whether the labels on the surface of the bottles are complete, whether the characters are clear and readable, and whether the bottles are cracked or broken.

Advantages of the 360° exterior lens

Efficient Inspection

The 360° outer wall lens can inspect all aspects of a product in a short period of time, which greatly improves inspection efficiency. Compared to traditional manual inspection or single-angle machine inspection, the 360° exterior lens can inspect multiple products at the same time, reducing inspection time and costs.

Accurate Inspection

POMEAS' 360° exterior lenses use high-precision optics and advanced image processing technology to enable accurate inspection of product appearance. Whether it's a small defect or a tiny character, it can be accurately recognised and detected, ensuring that the product quality is up to standard.

Adaptable

The 360° outer wall lens is suitable for inspection of products of various shapes and sizes, whether they are round, square or irregularly shaped. At the same time, the lens can also be adjusted and optimised according to different inspection needs, to meet the individual inspection requirements of different companies.

Easy Integration

POMEAS 360° exterior lenses can be seamlessly integrated into a wide range of automated inspection equipment and production lines. Whether you are building a new line or upgrading an existing one, you can easily integrate the 360° exterior lens to improve productivity and product quality.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com