In industrial production, accurate measurement of bearings is crucial. With the development of technology, POMEAS on-line projected image measuring machines have shown their unique advantages in the field of bearing measurement.

Measurement context

In the modern bearing production process, various parameters of bearings need to be measured accurately to ensure that their quality and performance meet the standards. Traditional measurement methods may suffer from inefficiency and lack of precision, while the emergence of POMEAS on-line projected image measuring instrument provides a better solution for bearing measurement.

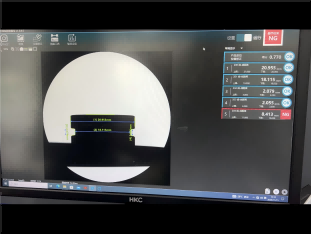

Measurement results

Measurement Advantages

1, fast measurement: when measuring bearings, just place the bearing on the measuring platform, the measuring instrument can quickly obtain the measurement results. This ability to measure quickly is of great significance to companies that produce bearings on a large scale. It can greatly improve production efficiency and reduce the time spent in the measurement process, making the production process smoother and avoiding production delays caused by the long measurement process.

2, high measurement accuracy: the measurement accuracy of the measuring instrument is as high as 0.08 um. For bearings, which require very high precision parts, such high precision measurement capability can accurately detect the bearings in the size, shape and other aspects of the small deviations. Whether it is the bearing's inner diameter, outer diameter, raceway size or roller dimensional accuracy, can be accurately measured, thus ensuring the high quality of the bearings, which helps to improve the stability and reliability of the bearings in the use of the process, reduce the mechanical failure caused by the bearing accuracy problems.

3, easy to operate: the operator can quickly learn and master the use of the measuring instrument. This means that companies do not need to spend a lot of time and cost of complex training for employees. New employees can get up and running in a short time, reducing human resource costs and training cycles. The simple operation interface and process also reduces measurement errors caused by human error, improving the accuracy and reliability of measurement results.

4, easy to integrate: POMEAS in-line projected image measuring machine can be easily placed in the assembly line and other production equipment. This ease of integration allows it to fit perfectly into existing bearing production processes. Whether in an automated production line or a semi-automated production environment, it can work with other equipment to further improve the degree of automation and productivity of the entire production system, while also facilitating the upgrading and transformation of the company's equipment.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com