Features of continuous zoom lens with double-rail construction

-

High precision and efficiency: The lens has a built-in double-guide linear motion structure, this design not only improves the motion precision, but also reduces the coefficient of friction, which improves the working efficiency and stability of the lens.

-

Fast and accurate magnification: The dual-guide structure makes the lens more fluid during the magnification process, enabling it to quickly and accurately reach the desired magnification without the need for cumbersome adjustments back to the zero position or to a magnification smaller than the target magnification.

-

Built-in scale monitoring: A scale is integrated inside the lens to record and monitor the position of the lens in real time, ensuring the accuracy and efficiency of the zoom.

-

Superior Optical Performance: By eliminating optical effects and friction losses that cannot be avoided in conventional zoom lenses, continuous zoom lenses with a dual-guide structure offer significant improvements in optical performance, precision, stability, and service life.

-

High Contrast Imaging: Adopting the core adjustment method to solve the impact of the optical element's centre bias on the imaging contrast, making the imaging clearer and with higher contrast.

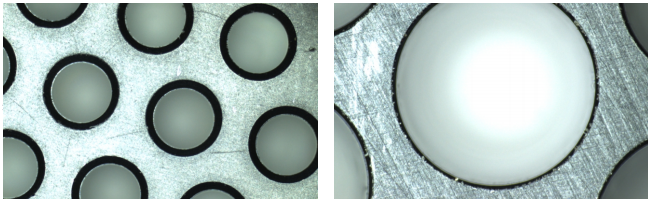

The advantages of continuous zoom lens measurement with dual-guide construction, using filters as an example

-

Magnification range from 1X to 4X: The lens is able to easily achieve magnification from 1X to 4X, which meets the need for precise measurements of different sizes and details.

-

High-precision measurement: Due to the high precision and stability of the lens, the accuracy and reliability of the measurement results can be ensured.

-

Fast Response: The lens is able to respond quickly to measurement commands, reducing measurement time and increasing work efficiency.

-

Strong applicability: It is not only applicable to the measurement of filters, but also widely used in other occasions that require high-precision measurement.

Continuous zoom lenses with double-guide structureApplicationsIndustries

-

Semiconductor industry: used in chip character defect detection, IC components PIN foot coplanarity detection and other precision inspection areas.

-

Hardware industry: used for dimensional measurement of hardware, surface defect detection, etc.

-

Automotive industry: Used for dimensional measurement of automotive parts, identification of appearance defects, etc.

-

Mobile phone industry: used for mobile phone screen size measurement, headset module chip bubble defect detection, and so on.

-

Plastic industry: for dimensional measurement of plastic parts, material defect detection, etc.

In addition, the continuous zoom lens with dual-guide structure is also suitable for PCB board gluing inspection, LED core board surface defects and size inspection, ITO film pattern recognition inspection and many other fields. Its superior performance and wide range of applications make the double-guide structure continuous zoom lens an important part of the machine vision system.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com