Application of in-line image measuring instrument in tool angle measurement

In the field of machining, the accuracy and performance of tools are directly related to the quality and efficiency of machined parts. Therefore, it is particularly important to measure the parameters of the tool accurately.

Measurement requirements:

The angle and width of a tool's flute is an important indicator of its performance. During the measurement process, it is necessary to ensure the accuracy and reliability of the data. The specific requirements are as follows:

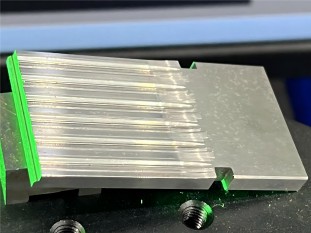

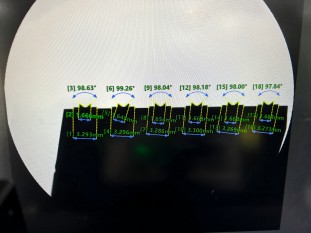

(1) Groove angle measurement: Accurately measure the angle between the tool groove and the tool body to assess the cutting performance and stability of the tool.

(2) Groove width measurement: Accurately measure the width of the tool groove to ensure that the tool can maintain a stable cutting force during the cutting process.

Measurement Program:

The POMEAS HM series of in-line image measuring instruments are characterized by high accuracy, integration and intelligent operation, making them ideally suited for in-line real-time tool measurement.

Measurements:

Program Strengths:

1、online real-time fast measurement: POMEAS online image measuring instrument HM series adopts advanced image acquisition and processing technology, which can capture the image of the tool in real time and quickly process and analyze the data. This greatly improves the measurement efficiency and enables timely quality inspection and feedback of tools in the production process.

2、high-precision measurement: the measuring instrument adopts high-precision optical system and image processing algorithms, which can realize the accurate measurement of the angle and width of the tool groove. Its measurement accuracy can meet the high precision requirements for tools in the field of machining.

3、multi-industry versatility: POMEAS online image measuring instrument HM series is not only suitable for tool measurement, but also widely used in automotive parts, aerospace, electronics manufacturing and other fields. Its versatility makes the gauge able to meet the needs of different industries for high precision measurement.

4、high integration: the gauge can be seamlessly integrated with existing production lines to realize automated measurement and data acquisition. This reduces the difficulty and error of manual operation and improves the overall efficiency and stability of the production line.

5、Intelligent operation: POMEAS HM series on-line image measuring instrument is equipped with intelligent operation interface and control system, which makes the operation easier and more intuitive. Users can set measurement parameters and view measurement results via touch screen or remote control system, which greatly improves the convenience and flexibility of measurement.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com