LCD Line Inspection Background

In the production and quality control process of LCD (Liquid Crystal Display), line inspection is a crucial link. As the line width and line spacing of LCD lines are very small, requiring high pixel resolution, while ensuring a sufficient field of view, the inspection process requires high accuracy, fast response time, and can avoid damage or contamination of the LCD. Traditional detection methods, such as the reference comparison method, non-reference calibration method, etc., although to a certain extent to meet the detection needs, but there are often complex operations, memory consumption, alignment accuracy requirements and other issues.

Detection programme

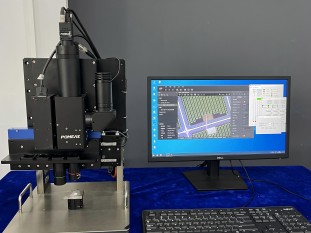

POMEAS laser autofocus microscopes offer significant advantages in LCD line inspection, greatly improving inspection efficiency and accuracy while protecting the integrity of the LCD and prolonging its service life.

Advantages of laser autofocus microscopy

1. High-precision focusing: laser auto-focusing technology enables the system to quickly and accurately capture the fine structure and features of LCD lines, which is crucial to ensure the accuracy and reliability of the inspection results.

2. fast response: the system has a fast response speed, can quickly adjust the focus to adapt to the different positions and angles of the LCD line inspection needs, thus greatly improving the detection efficiency and reduce waiting time.

3. non-contact detection: non-contact detection methods, to avoid the traditional detection methods may cause damage to the LCD and pollution, to help protect the integrity of the LCD, to extend its life.

4. High-definition imaging: the system can produce high-definition images, enabling the inspector to clearly observe the fine structure of the LCD line and defects, which helps to accurately determine the quality of the LCD and improve the accuracy of the inspection.

5. Integrated and Intelligent Design: The laser autofocus microscope system adopts a highly integrated design, integrating the core components such as industrial camera, laser focusing module, point light source, and APO (apochromatic) objective module, simplifying the system structure and reducing the maintenance cost. At the same time, the intelligent design concept allows users to simply place the LCD to be observed on the platform, click the ‘AUTO’ button, the system can automatically complete the focus and magnification adjustment, greatly reducing the user's operating difficulties.

6. Multi-functional applications: In addition to its application in LCD line inspection, the laser autofocus microscope system also shows great potential for application in many fields such as material science, biomedicine, semiconductor inspection, etc. Its multi-functional advantages make the system a popular choice for scientific research. Its multifunctional advantages make the system become a powerful assistant in the field of scientific research and industrial inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com