In the grand stage of industrial production, quality control is the most important thing, and the zoom lens is like a loyal defender with ‘fiery eyes’, building an impenetrable quality defence for industrial inspection.

In the microcosm of electronic component production, zoom lenses come into their own. For those tiny chips, the fineness is beyond imagination, every pin, every circuit is related to the final performance of the product. The zoom lens can quickly switch from low magnification to high magnification, just like the Monkey King's fiery eyes, accurately capturing the tiny scratches on the surface of the chip, solder joints, or short circuit problems. In the densely-packed pins, not a single flaw can escape its discerning eye, to ensure that each chip can enter the next process in a perfect state.

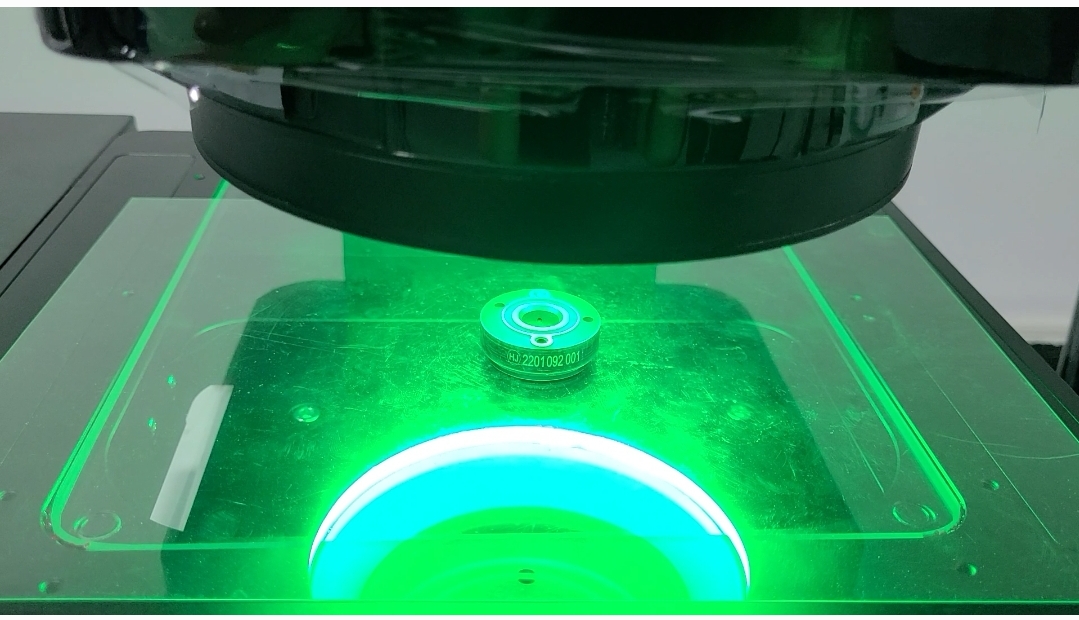

In the field of machinery manufacturing, the quality of components directly affects the performance and life of the entire machinery and equipment. Whether it is a precision gear or a complex bearing, the zoom lens can play a key role. When testing gears, it can first observe the overall contour of the gear and the integrity of the tooth shape at a lower magnification, and then zoom in to focus on the individual tooth surface to see if there is uneven processing grain, tiny cracks and other problems. For bearings, the zoom lens is able to penetrate into the tiny gaps between the balls and raceways to check surface finish and wear. Even extremely minor defects, such as wear marks of a few microns, can be keenly detected by it, avoiding the flow of problematic parts into the assembly process, thus guaranteeing the reliable operation of mechanical equipment.

In the automotive manufacturing industry, the zoom lens is also a powerful assistant for quality inspection. As a core component, the automobile engine has a complex internal structure and many parts. The zoom lens can go deep inside the engine block to check the wear and tear of the piston surface, the sealing of the valve and other key parts. During the assembly process of automotive parts, the zoom lens can be used to inspect the tightening of bolts in detail, ensuring that each connection point meets quality standards and preventing safety hazards caused by loosening.

In the automated production line, the zoom lens works closely with the automated inspection system and becomes a key link in efficient quality inspection. It can quickly and accurately inspect the products on the assembly line one by one, whether they are in high-speed motion or stationary, they can be scanned by its ‘wise eye’ in an instant. Moreover, the zoom lens can automatically identify and mark unqualified products according to preset quality standards, stopping quality problems on the production line and escorting large-scale, high-efficiency industrial production.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com