Telecentric Lens Measurement Solutions Accessories Selection Guide

Telecentric Lens Measurement Solution Advantages

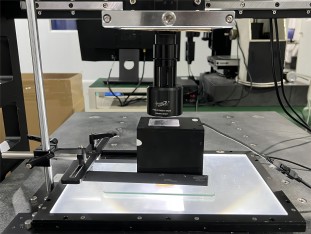

Telecentric lenses are high-precision, high-efficiency industrial lenses with consistent magnification, low aberrations, and other high quality imaging qualities, making them ideal for high-precision dimensional measurement and defect detection. Its main advantages include:

1, high-precision measurement: telecentric lenses can correct the parallax of traditional industrial lenses and maintain the consistency of image magnification, which will not change due to the change of object distance and is suitable for measurement of the object to be measured is not on the same object surface.

2, non-contact measurement: telecentric lens measurement has non-contact, can avoid measurement errors caused by contact and object damage.

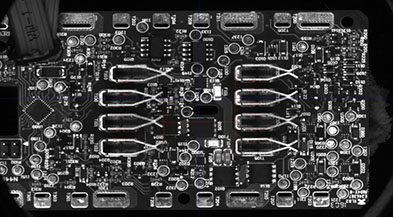

3, large depth of field and clear imaging: telecentric lens of large depth of field and clear imaging capabilities, so that it can detect very small defects, to achieve comprehensive detection.

4, improve productivity: equipped with telecentric lens inspection programme can be completed in a very short period of time a series of high-precision measurements, and its rapid response, thereby reducing the defect rate and improving productivity.

Accessories

Visual Light Sources

(1) Parallel light source: With telecentric lens inspection, it can eliminate the phenomena such as blurred edges caused by diffuse light source, obtain clear and sharp images with clear edges, and improve inspection accuracy. Suitable for cylindrical, round and three-dimensional objects image size measurement.

(2) Coaxial light source: uniform diffusion, can reduce shadows, very little flare, with telecentric lens, suitable for detecting high brightness, easy to reflect the object.

(3) Ring light source: uniform brightness, can highlight the information of the measured object. Combined with telecentric lens, it can obtain higher quality images, suitable for precision electronic parts defect identification and industrial quality inspection applications.

Industrial Cameras

(1) Camera resolution: the choice of camera resolution depends on the project requirements. High resolution brings a large amount of image data, the complexity of the later algorithm processing is high, and the general resolution of the camera, the frame rate is generally not too high.

(2) Sensor size: the larger the sensor size, to a certain extent, that the camera can accommodate more pixels, the larger the imaging frame.

(3) Interface type: telecentric lenses are mainly designed to match around industrial cameras, and the interface between the lens and the camera is generally a conventional standard interface, such as C interface, F interface, M42 interface, M58 interface and so on. In the selection, to ensure that the lens and camera interface match.

Sensors

(1) Sensors are used to capture image information imaged by telecentric lenses and convert it into electrical signals for processing. The selection of the sensor takes into account parameters such as its sensitivity, resolution and response speed to ensure that it can meet the needs of the measurement programme.

The selection of accessories for telecentric lens measurement solutions needs to be based on specific measurement needs and application scenarios. When selecting, factors such as the type of lens interface, working distance, field of view, spectral characteristics, aberration rate and the size of the mechanical structure should be considered, as well as the selection of light sources, cameras and sensors to ensure that the selected accessories can meet the needs of the measurement programme, and build the most cost-effective vision programme.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com