Computer Heat Sink Measurement Background

In computer hardware, heatsinks play a crucial role, they are responsible for effectively radiating the heat generated by the CPU, graphics card and other heat-generating components to maintain the stable operation of the computer. With the continuous improvement of computer performance, the design of heatsinks has become more and more complex, and their size and shape have a direct impact on the heat dissipation effect. Therefore, accurate size measurement and arc detection of the heatsink is an important step to ensure that its heat dissipation performance meets the design requirements.

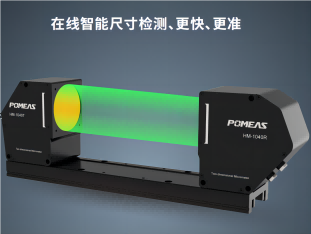

Dimensional Measurement and Arc Inspection of Computer Heat Sinks: POMEAS In-Line Image Projection Measuring Instrument

The POMEAS in-line image projection measuring instrument provides an efficient and accurate solution for the dimensional measurement and arc detection of heat sinks. Combining image technology and measurement technology, the gauge is able to accurately locate and measure heat sinks through high-definition image acquisition and sophisticated algorithms.

Size Measurements:

① POMEAS In-Line Image Measuring Instrument adopts dual telecentric optical lenses combined with a high-resolution camera, which is capable of capturing the fine features of heat sinks.

② The software interface is friendly and the operator can easily set up the measurement procedure to accurately measure the key dimensions such as length, width and height of the heat sink.

③ Measurement data can be displayed and saved in real time, which is convenient for subsequent analysis and processing.

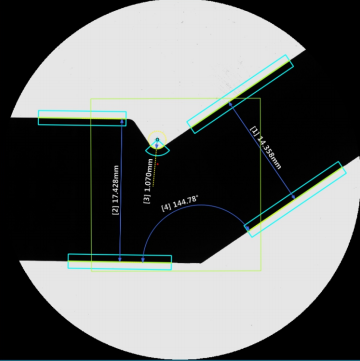

Circular Arc Detection:

① The high-precision image analysis system of the Image Measuring Instrument enables precise inspection of the rounded part of the heat sink.

② By zooming in and out on the image, the operator can view the shape and size of the arc in detail.

③ The measuring instrument can generate a detailed inspection report, including key parameters such as the radius and angle of the arc, which provides powerful support for the design and manufacture of heat sinks.

Measurements:

Online Image Projection Measurement Advantage:

1. High precision: POMEAS in-line image measuring instrument adopts high-precision optical system and algorithm, which is able to achieve precise measurement of heat sink size and accurate detection of arc part.

2. Fast and efficient: the measurement speed is fast, and the measurement of multiple parts can be completed within 1 second, which greatly improves the production efficiency.

3. Intelligent: support remote monitoring, managers can view the measurement data and images in real time in the office, convenient for production management.

4. Wide applicability: POMEAS online image measuring instrument is not only suitable for the measurement and inspection of heat sinks, but also can be widely used in machinery, electronics, moulds, injection moulding, hardware, rubber and other fields.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com