In manufacturing, the accuracy and quality of sheet metal parts are critical to the overall performance of the product. Therefore, accurate measurement of the contour of sheet metal parts is a critical step in ensuring product quality. In this paper, we will introduce in detail a visual image-based sheet metal contour measurement device that uses advanced measurement techniques and components to provide high accuracy and efficiency.

Sheet metal parts measurement background

As an important part of the manufacturing industry, sheet metal parts are widely used in many fields such as automotive, aerospace, electronics and communications. With the advancement of science and technology and the development of industry, the precision requirements for sheet metal parts are getting higher and higher, and the traditional measurement methods have been difficult to meet the needs of modern manufacturing. Therefore, a more efficient and accurate measurement method is needed to meet this challenge.

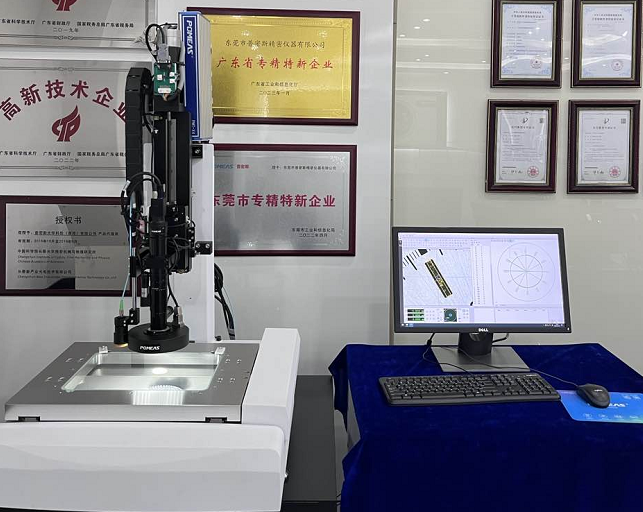

Sheet metal parts measuring equipment

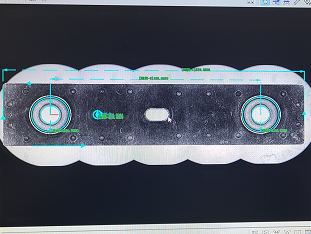

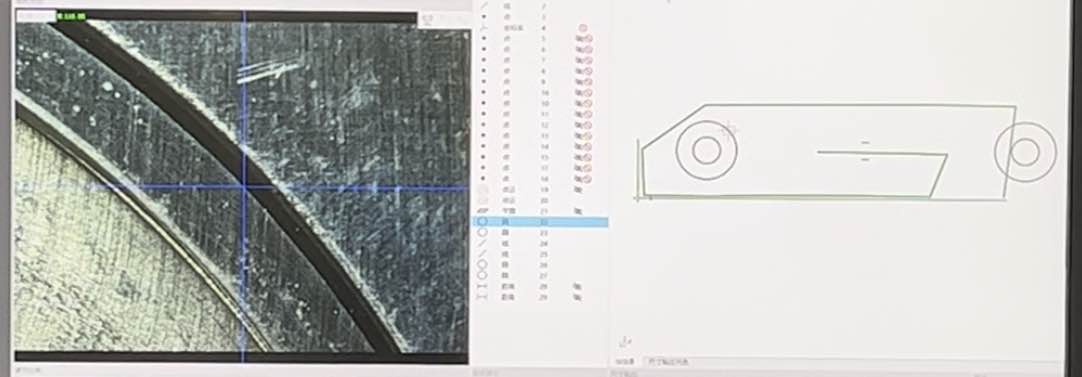

In order to meet the high precision requirements of sheet metal part measurement in modern manufacturing industry, we have adopted an advanced vision image measurement solution. The solution utilises a high resolution camera and advanced image processing algorithms to enable fast and accurate measurement of sheet metal part contours.

Measurement programme components:

POMEAS 6.5X zoom lens measurement module

The POMEAS 6.5X zoom lens measurement module is one of the core components of this measurement solution. It uses high precision zoom technology to provide clear imaging of sheet metal parts at different magnifications. This zoom capability allows the measurement equipment to be applied to sheet metal parts of different sizes and shapes, greatly improving the flexibility and accuracy of the measurement.

POMEAS Spot Spectrometry Sensors

A point spectrum measurement sensor is another important measurement component. It is capable of capturing small changes in the surface of an object and converting this information into a digital signal for processing. In the measurement of sheet metal parts, the point spectral measurement sensor is able to accurately measure the contours and surface morphology of sheet metal parts, providing a reliable basis for subsequent data analysis and processing.

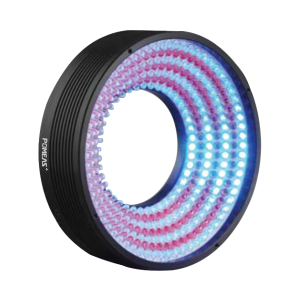

Ring Light Source

The ring light source is an auxiliary component designed to improve measurement accuracy. It provides uniform and stable lighting conditions, enabling the camera to capture clearer and more accurate images. In sheet metal part measurement, the ring light source reduces the effect of uneven lighting on the measurement results and further improves the accuracy of the measurement.

Test results:

The sheet metal contour measuring equipment adopts an advanced visual image measuring solution and is equipped with components such as a high-precision zoom lens measuring module, a point spectral measuring sensor and a ring light source. The synergy of these components enables the measuring equipment to achieve fast and accurate measurement of the contour of sheet metal parts, providing strong support for the development of modern manufacturing.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com