Detect metal flange requirements:

As an important part of pipeline connection, the accuracy of the dimensions of metal flanges is directly related to the reliability and safety of the connection. Therefore, there are strict requirements for the dimensional inspection of metal flanges. The testing items usually include key parameters such as the centre distance of the flange, the outer diameter size, the number of flange holes and the hole distance.

1、Centre distance: that is, the distance of diagonal holes on the flange, which is the key size to ensure the accuracy and stability of the flange connection.

2、Outer diameter size: the diameter of the outer edge of the flange disc, which has an important influence on the selection and use of the flange.

3、Number of flange holes and hole distance: the number of round holes on the flange and the distance between the holes, these parameters are crucial for the bolting and sealing performance of the flange.

Detection programme:

In order to meet the demand for high-precision and high-efficiency dimensional inspection of metal flanges, POMEAS IMAGE 3 image dimensional measuring instrument is used for inspection. The measuring instrument combines high-resolution dual telecentric lenses with intelligent image processing technology, featuring one-button flash measurement, large field-of-view overall imaging, auto-focus, etc., which can easily realise fast and accurate measurement of flange dimensions.

High Accuracy Measurement: POMEAS IMAGE 3 adopts high resolution lens and advanced image processing algorithms to achieve micron-level precision measurement of flange dimensions, ensuring the accuracy of inspection results.

One-button Flash Measurement: The easy-to-understand interface of the gauge allows you to start the measurement with just one button, eliminating the need for complicated operating steps and greatly improving the inspection efficiency.

Large field of view overall imaging: the measuring instrument has a large field of view overall imaging function, able to capture the full size of the flange at once, without the need to move the lens several times, saving the inspection time.

Auto Focus: The auto focus function of the measuring instrument can automatically adjust the focal length of the lens to ensure the clarity of the captured image and improve the accuracy of the measurement.

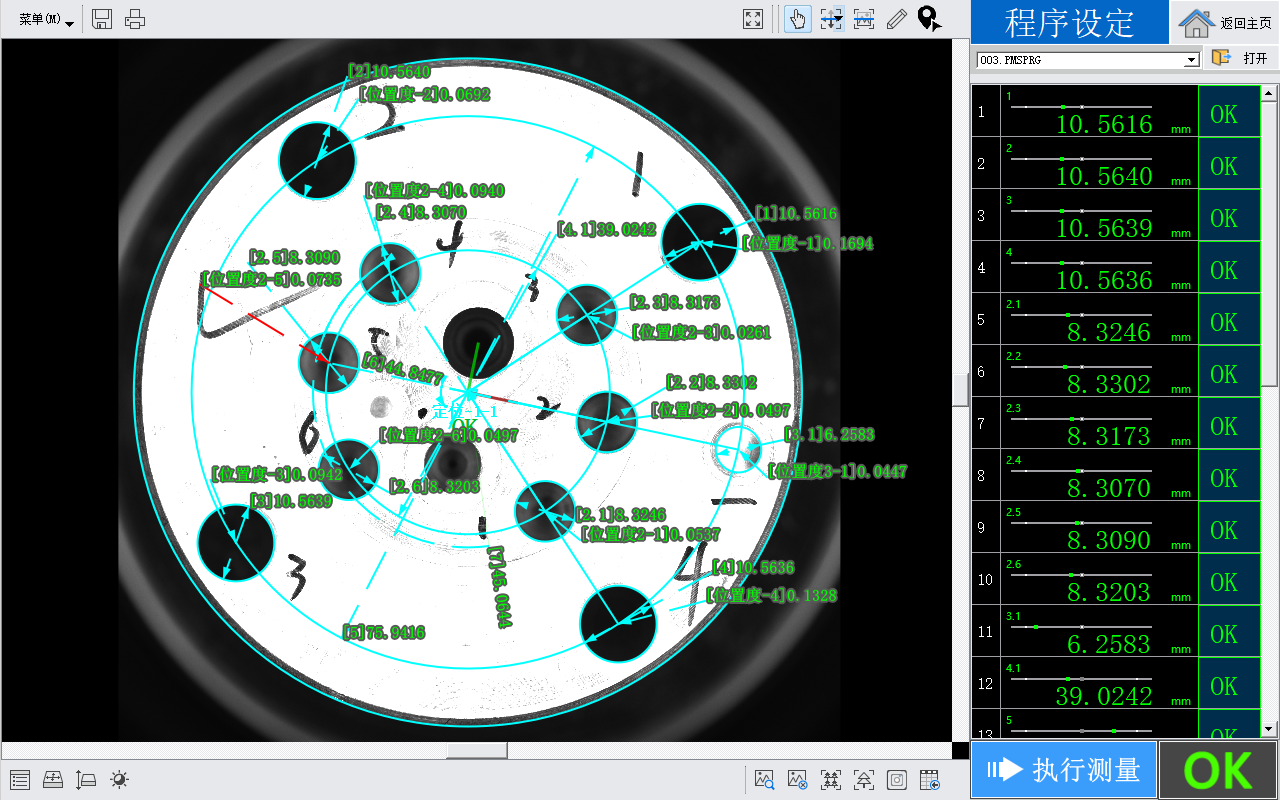

Testing results:

Programme Advantage:

Efficiency: The POMEAS IMAGE 3 Image Dimension Gauge enables rapid measurement of flange dimensions, greatly improving inspection efficiency and shortening production cycle time.

Accuracy: The use of high resolution lenses and advanced image processing technology enables flange dimensions to be measured with micron-level precision, ensuring the accuracy of inspection results.

Ease of operation: The operator interface of the measuring instrument is simple and easy to understand, and the measurement is initiated by a single button, without the need for complicated operating steps, which reduces the difficulty of operation.

Applicability: POMEAS IMAGE 3 is not only suitable for metal flange dimensional inspection, but also can be widely used in electronics, hardware, automotive, mobile phones, industrial manufacturing and other fields of precision dimensional measurement.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com