Image Gauge (Flash Gauge) Quickly Measures Hole Diameter and Hole Depth

In industrial production and precision manufacturing, accurately measuring bore diameter and depth is a critical step in ensuring product quality and performance. However, traditional methods often face many challenges when facing these measurement tasks, such as the difficulty of lighting the holes, which makes it difficult to observe the internal details clearly, and the limitation that ordinary image measuring instruments cannot directly measure the height and depth.

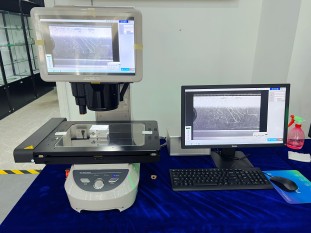

To solve these challenges, POMEAS has launched the IMAGE3 MAX II image dimensioning system, which revolutionizes the accurate measurement of bore hole diameter and depth with its unique performance and design.

Core Advantage:

Non-Contact, High-Precision Measurement: IMAGE3 MAX II integrates advanced machine vision technology with high-precision sensors, enabling high-precision, high-speed dimensional measurements without contacting the object being measured. This not only avoids the damage that may be caused by traditional contact measurement, but also greatly improves the accuracy and efficiency of measurement.

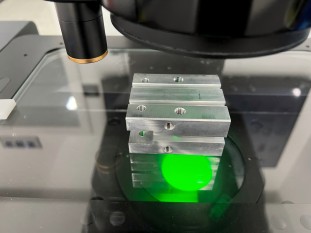

Point Spectrum Sensor Depth Measurement: To address the challenge of hole depth measurement, POMEAS has skillfully introduced the point spectrum sensor technology. The sensor is capable of emitting light of a specific wavelength and calculating depth information by receiving the time difference or phase difference of the reflected light, thus realizing non-contact hole depth measurement. This innovative design allows the IMAGE3 MAX II to measure complex internal structures with ease.

3D Contour Scanning: In addition to depth measurement, the IMAGE3 MAX II has a powerful 3D contour scanning function. It captures the surface morphology of the object to be measured in all directions and generates a highly accurate 3D model. This function is especially important for borehole diameter measurement, as it can clearly show the shape of the inner wall of the borehole, ensuring the comprehensiveness and accuracy of the measurement results.

Intelligent operation and data analysis: Equipped with an intuitive and easy-to-use interface and powerful data analysis software, the IMAGE3 MAX II is able to automate measurement tasks and process and analyze measurement data in real time. Measurement reports can be easily exported to support product quality control and process improvement.

Application Scenarios:

1. Bore diameter and depth measurement of precision mechanical parts

2. Precision dimensional inspection of aerospace components

3. Internal structure analysis and quality control of electronic products

4. Critical dimensional verification in medical device manufacturing.

POMEAS IMAGE3 MAX II image dimensioning system solves the problem of bore diameter and depth measurement with its unique performance and design. It not only improves the accuracy and efficiency of measurement, but also brings users a more convenient and intelligent measurement experience.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com