In the field of precision manufacturing and inspection, the lens as the core component of the vision system, its performance directly affects the accuracy and efficiency of the inspection results. There are significant differences between zoom lenses and traditional lenses in several aspects, especially in the inspection of tools and other applications that require a high degree of precision, these differences are particularly obvious.

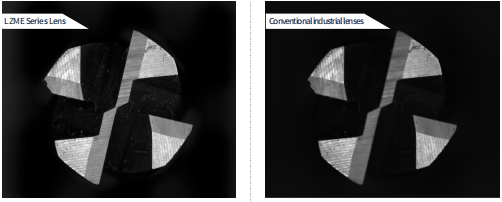

Clarity and Sharpness

1、Zoom Lens: The zoom lens, with its advanced optical design, is able to demonstrate a high degree of sharpness while maintaining a high degree of clarity. This means that when inspecting a tool, both the overall contour of the tool and the fine edge of the cutting edge are clearly and sharply rendered. This characteristic is essential for accurate measurement of tool dimensions and for assessing the quality of the cutting edge.

2、Conventional lenses: In contrast, conventional lenses can be slightly less clear and sharp. Especially at higher magnifications or when the object is rich in detail, conventional lenses can suffer from blurred images and soft edges, which can affect the accuracy of inspection results.

Aberration Control

1、Variable-magnification lens: The variable-magnification lens is designed with aberration control in mind. By optimizing the structure of the optical path and adopting high-precision lens materials, the aberration rate of the image is effectively reduced. This makes it possible to ensure that the geometry of the image is not distorted when inspecting the tool, regardless of how the tool is placed or moved, providing a reliable basis for subsequent size measurement and shape analysis.

2、Traditional lenses: Traditional lenses may have certain limitations in terms of distortion control. Especially in large viewing angle or high magnification, the image may have obvious barrel distortion or cushion distortion, affecting the accuracy of the observation results.

Imaging Quality

1、Variable-magnification lenses: Variable-magnification lenses are not only characterized by high resolution and low aberrations, but also capable of maintaining stable imaging quality under various lighting conditions. Its high-resolution characteristics make the tiny details on the tool can also be clearly captured, providing inspectors with a wealth of image information.

2、Traditional lenses: Traditional lenses may be affected by a variety of factors in terms of image quality, such as lighting conditions, lens material, manufacturing process. These factors may lead to image noise, color distortion and other problems, affecting the reliability of the inspection results.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION