Detection background:

Scanning the battery pack contour is an important part of the battery pack manufacturing process, which is significant to ensure the dimensional accuracy, shape consistency and smooth subsequent assembly of the battery pack. By scanning the battery pack contour, high-precision three-dimensional data can be obtained, thus realizing the precise control and optimization of the battery pack quality.

Detection Program:

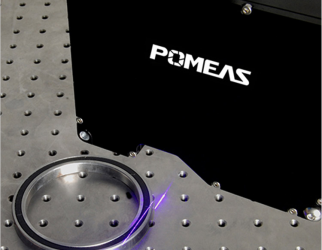

POMEAS line laser sensors have non-contact measurement and high speed scanning in scanning the battery pack contour, which can ensure the accuracy, efficiency and reliability of the measurement results. Therefore, the use of line laser sensors for contour scanning is an effective means of quality control in the battery pack manufacturing process.

Program Strengths:

1、High-precision measurement: The line laser sensor utilizes the principle of laser triangulation, which can realize high-precision measurement of the battery pack contour. Its high resolution and fast sampling frequency can capture the subtle changes in the battery pack contour and ensure the accuracy of the measurement results.

2、Non-Contact Measurement: The line laser sensor adopts a non-contact measurement method, which avoids the wear and tear, deformation and other problems that may be brought about by the traditional contact measurement. This measurement method not only improves the measurement accuracy, but also extends the service life of the measurement equipment.

3、Efficient Scanning: The line laser sensor has the characteristic of high speed, which can complete the rapid scanning of the battery pack profile in a short period of time. This greatly improves the measurement efficiency, reduces production costs, and is suitable for large-scale production lines for rapid inspection needs.

4, High Repeatability: line laser sensor has excellent repeatability accuracy, which can ensure the consistency of the results of multiple measurements. This helps to reduce the accumulation of measurement errors and improve the reliability of measurement results.

5、Wide applicability: the line laser sensor is suitable for a variety of different types of battery pack contour measurement. No matter how the shape, size or material of the battery pack changes, the line laser sensor can provide stable and accurate measurement results.

6、Data visualization and analysis: the line laser sensor scanning the battery pack contour data can be output in real time and visualization. This helps production staff to intuitively understand the dimensional characteristics and shape changes of the battery pack, providing strong support for subsequent assembly, commissioning and optimization. At the same time, through the analysis of the measurement data, it is also possible to identify potential quality problems and make timely improvements.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com