Detection background:

With the rapid development of modern manufacturing industry, high precision measurement of internal diameter is crucial in modern manufacturing industry, especially in the field of automobile, aerospace, precision instruments, etc., the accuracy of internal diameter size is very high. As one of the important dimensions of many key components, the accuracy of the inside diameter directly affects the performance and reliability of the product. Traditional methods of measuring inside diameter, such as vernier calipers and inside diameter micrometers, have a certain degree of accuracy, but there are problems such as slow measurement speed and susceptibility to human factors. Therefore, it is particularly important to develop an efficient and accurate internal diameter measurement method.

Solution:

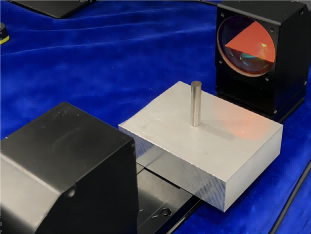

POMEAS In-Line Image Projection Measuring Instrument HM series is a non-contact measuring device that utilizes a high-precision optical system and image processing algorithms to accurately measure the inside diameter of the object being measured. The solution has the advantages of fast measuring speed, high accuracy and easy operation, and is suitable for measuring the inner diameter of various complex shapes and sizes.

Programmatic Advantage:

1、High precision: adopting high-precision optical system and advanced image processing algorithm to ensure the accuracy of measurement results.

2、Non-contact measurement: avoid the traditional contact measurement may bring scratches, deformation and other problems, suitable for a variety of materials measurement.

3、Fast measurement: high degree of automation, greatly reducing the measurement time, improve work efficiency.

4、Easy to operate: the interface of the equipment is simple and clear, easy to operate, reducing the requirements of the operator's skills.

5、Multi-functionality: in addition to internal diameter measurement, it can also be used for the measurement of external diameter, length, angle and other dimensions.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION