In modern industrial production and scientific research, precise measuring tools are of vital importance. With its advanced technology and versatility, the spectral thickness gauge has become a right-hand man in many fields.

Principle of spectral thickness measurement:

Spectroscopic thickness gauges utilize a specific wavelength of light to illuminate a measurement slide. When light strikes the surface of a slide, phenomena such as reflection, refraction and absorption occur. By analyzing the spectral characteristics of the reflected light, the thickness of the slide can be determined. Slides of different thicknesses interfere with the light to varying degrees, resulting in changes in the spectrum of the reflected light. The program accurately calculates the thickness of a slide by detecting and analyzing these spectral changes.

Spectral Thickness Gauge Composition:

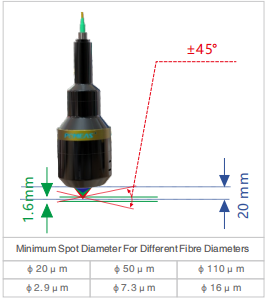

Spectral probe

(1) The spectral probe is one of the core components of a spectral thickness gauge. It is responsible for emitting light of a specific wavelength and receiving light reflected back from the measuring slide.

(2) The design accuracy and stability of the probe directly affect the accuracy of the measurement results. An advanced spectral probe can provide high-resolution spectral data to ensure the accuracy and reliability of the measurement.

Spectral control box

(1) The spectral control box serves to connect and control the spectral probe and the spectral control system.

(2) It can regulate and control the light emitted from the probe to ensure the stability and consistency of the light. At the same time, the control box is also responsible for receiving the spectral data from the probe and transmitting it to the spectral control system for processing.

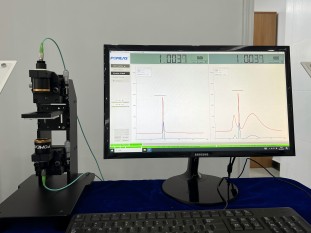

Spectral control system CCS

(1) The spectral control system is the brain of the spectral thickness gauge. It receives spectral data from the spectral control box and applies advanced algorithms to analyze and process it.

(2) The CCS is able to quickly and accurately calculate parameters such as the thickness of the measured slide and display the results on the instrument's display. At the same time, it can also parameterize and calibrate the instrument to ensure the accuracy and stability of the measurement.

Spectral Thickness Gauge Usage:

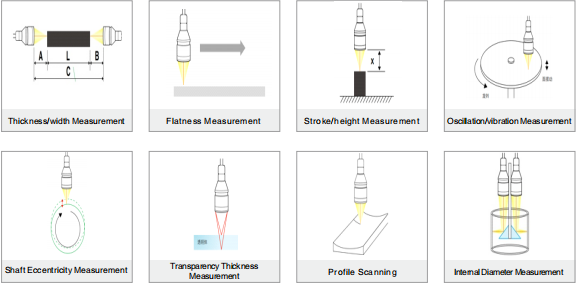

1. Height measurement: Spectral thickness gauges can be used to indirectly determine the height of an object by measuring the change in thickness of a slide. For example, in the electronics manufacturing industry, it can be used to measure the height of a chip to ensure the quality and performance of the product.

2. Thickness measurement: This is one of the main uses of spectral thickness gauges. It can accurately measure the thickness of a variety of materials, such as metal, plastic, glass and so on. In automotive manufacturing, aerospace and other fields, accurate thickness measurement is essential to ensure product safety and reliability.

3. Flatness : The flatness of an object can be assessed by measuring the thickness at different positions on a measuring slide. If the thickness of the slide varies significantly from position to position, the flatness of the object is poor. This is important in areas such as precision machinery manufacturing and optical component processing.

4. Segment Difference: Spectral thickness gauges can detect the difference in height between two neighboring surfaces, known as the segment difference. This is useful in industries such as electronics assembly and semiconductor manufacturing to ensure tight and reliable connections between different components.

5. Contour: The contour of an object can be determined by measuring the thickness of the edge of a measuring slide. This is important in the manufacture of parts and molds with complex shapes to ensure dimensional accuracy and surface quality of the product.

With their advanced measurement principles, sophisticated components and wide range of applications, POMEAS spectral thickness gauges provide accurate and reliable measurements of slide thickness, height, flatness, segmentation and contour.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com