In the field of industrial measurement and inspection, spectral confocal sensors play an increasingly important role. However, facing the many different specifications of spectral confocal sensors on the market, how to quickly select a product suitable for their application scenarios has become a problem for many users. The following will introduce you how to quickly select a spectral confocal sensor based on key parameters.

Measuring Distance:

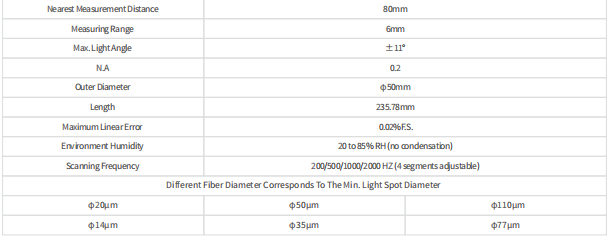

Measuring distance is the first factor to consider when selecting a model. Different application scenarios have different requirements for the measurement distance. For example, in some of the production line inspection of space constraints, the sensor needs to be able to achieve accurate measurement in a short distance; while in some large equipment monitoring scenarios, the sensor may be required to have a longer measuring distance.

You need to clarify the actual distance range between your measurement target and the sensor to ensure that the selected spectral confocal sensor can cover this distance range. Some sensors will provide greater accuracy at closer distances, while others will still perform well at longer distances.

Measurement Range:

The measuring range determines the span of dimensions that a spectral confocal sensor can effectively measure. If the object you need to measure has a large variation in size, then you need a sensor with a large measuring range.

For example, when measuring the thickness of a mechanical part, which can vary from a few millimeters to tens of millimeters, it is critical to select a spectral confocal sensor with a measurement range that covers this thickness variation interval. Otherwise, measurements may exceed the sensor's range and result in inaccurate measurements.

Spot Diameter:

Spot diameter directly affects the accuracy of the measurement and its suitability for small objects. Smaller spot diameters (e.g. 20um) provide higher spatial resolution and are suitable for measuring very fine surfaces or minute features.

When measuring objects such as microstructures, precision electronic components, etc., a 20um spot diameter allows for precise positioning and measurement of the target point. However, smaller spot diameters may be less efficient when measuring large areas.

A spot diameter of 50um is a more moderate choice, which ensures a certain degree of accuracy while also being more adaptable to measuring objects of slightly larger sizes.

The 110um spot diameter is suitable for measuring larger areas or objects that do not require the highest level of accuracy. For example, when measuring the surface flatness of large plates, a larger spot diameter allows for faster measurement of large areas.

N.A. (Numerical Aperture):

Numerical aperture is an important optical parameter of spectral confocal sensors. It is closely related to the sensor's resolution, ability to gather light, etc.

A higher N.A. value means that the sensor is able to collect more light, thus increasing the brightness and resolution of the image. Spectral confocal sensors with higher N.A. work better when measuring low reflectance objects or in low light environments.

Also, the N.A. value affects the depth of field of the sensor. A larger N.A. usually results in a shallower depth of field, which is of particular concern when measuring surfaces with different height differences and may require adjustments to the measurement strategy.

By comprehensively considering parameters such as measuring distance, measuring range, spot diameter, N.A., etc., you can quickly filter out the spectral confocal sensor that suits your application needs, thus providing a more accurate and efficient solution for industrial measurement and inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com