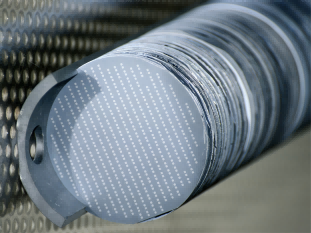

In-line image measuring instrument to measure electrode foil width

Measurement Background:

In the electronic manufacturing industry, electrode foil, as a key electronic component, its dimensional accuracy directly affects the performance and stability of electronic products. The width of electrode foil, as one of the important indexes, needs to be strictly controlled in the production process. The traditional manual measurement method is not only inefficient, but also easy to introduce human error, which is difficult to meet the dual demand for high precision and high efficiency in modern industrial production. Therefore, the adoption of automated, high-precision measurement means has become the key to solving this problem.

Measurement program: In-line image measuring instrument to measure the width of electrode foils

POMEAS in-line image measuring instrument captures the image of the electrode foil through the light-emitting side telecentric lens, and analyzes and processes the image using advanced image processing algorithms. The width information of the electrode foil can be accurately extracted by edge detection, image recognition and other techniques. At the same time, combined with a precision mechanical drive system and displacement measuring devices such as a grating scale, real-time, on-line measurement of the electrode foil width can be realized.

Measurement program advantages:

(1) High precision: the in-line image measuring instrument adopts high-resolution camera and advanced image processing algorithm, which can realize micron-level measurement precision and meet the high requirements of electrode foil width measurement.

(2) High efficiency: The automated measurement process greatly shortens the measurement time and improves the production efficiency. At the same time, it avoids errors that may be introduced by manual measurement and improves the reliability of measurement results.

(3) Easy to operate: The operation interface of the measuring instrument is simple and clear, so production personnel can easily get started. At the same time, the measurement process does not require contact with the electrode foil, avoiding possible damage or contamination caused by physical contact.

(4) Strong adaptability: the online image measuring instrument can be adapted to different specifications, different materials of the electrode foil measurement needs, has a high degree of versatility and flexibility.

After adopting the online image measuring instrument to measure the width of electrode foil, the quality control in the production process has been significantly improved. It not only improves the measurement efficiency and accuracy, but also reduces the production cost and scrap rate. At the same time, the measurement solution also provides strong support for the realization of automated production and intelligent management of electrode foils.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com