White Light Interferometric Profile Scanner Applying Coin Cell Batteries

Detecting Difficulties:

1. There is a wide variety of defects in the appearance of button batteries, mainly including scratches, rust spots, dirt, dents, glossy surfaces, etc., and the size of these defects is usually on the millimeter scale. Since the outer surface of the button cell is made of metal, the metal surface will produce serious reflections under the light source, which makes the sensor imaging and image processing difficult.

2. With the traditional metal steel plate and other detection is different, the surface of the button cell is also printed with characters, these characters will cause interference with the image sensing system. The limitations of the button cell production process also lead to the metal surface is difficult to ensure absolute flatness, micro-surface unevenness exists, which triggers severe diffuse reflection. At the same time, the surface character engraving is not standardized enough, there is a positional offset, the depth of the phenomenon of different shades, making the image after imaging the image character thickness and position of the larger changes, further increasing the difficulty of the optical circuit system design and image processing.

3. In order to improve detection efficiency, the production will usually use multi-point detection, each detection point under the realization of multi-cell target simultaneous detection. However, this makes it difficult to ensure that the light source is uniformly irradiated on the surface of each cell, which makes subsequent processing difficult. In addition, the tilt angle of the characters on the positive side of the cell is randomly varied on the image, which makes image correction a difficult task in research.

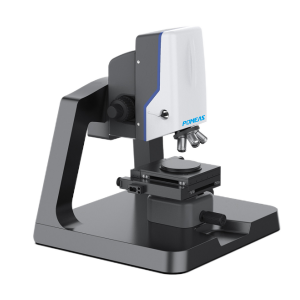

The POMEAS white light interferometric profile scanner, as a high-precision physical property testing instrument, can be applied in the inspection of button batteries. POMEAS white light interferometry is based on the principle of white light interference, which resolves the relative height or surface topography of the sample under test by measuring the interference fringes of the reflected light. This technique has a very high resolution, can measure most parameters, and the device is relatively simple.

1、Surface roughness measurement: The surface roughness of a button cell is one of the most important indicators for assessing its quality. White light interference contour scanner can accurately measure the surface roughness of the button cell surface, to help identify surface defects, such as scratches, dents and so on.

2、Character recognition and positioning: Although the characters on the surface of the button battery will cause interference with the image sensing system, but the white light interference contour scanner can accurately identify and locate these characters through high-resolution imaging and image processing technology, so as to realize the rapid identification and classification of battery models.

3、Multi-point detection and parallel processing: in order to improve detection efficiency, white light interference contour scanner can be configured with multi-point detection system to achieve simultaneous detection of multiple button batteries. By optimizing the light source design and image processing algorithms, it can ensure the uniform irradiation and accurate imaging of each battery surface, thus improving the accuracy and efficiency of detection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com