Point Spectral Contrast Measurement of Electrode Foil Thickness Application Example

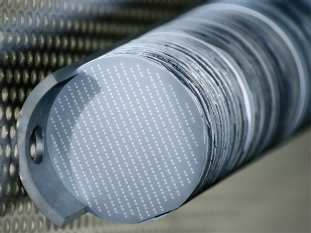

In industrial production, accurate measurement of the thickness of electrode foils is a critical part of ensuring product quality. As an important electronic material, the uniformity and accuracy of the thickness of electrode foil directly affects the performance and reliability of electronic products.

Measurement Background:

Thickness measurement of electrode foils has always been a challenging problem. Since electrode foils usually have small thicknesses and are made of special materials, conventional measurement methods often have difficulty in meeting the requirements for high-precision measurements. In addition, electrode foils may be affected by various factors during the production process, such as temperature, humidity, tension, etc., which further increases the difficulty of thickness measurement.

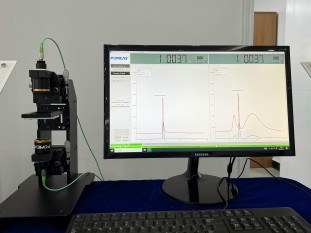

Measurement program: POMEAS Spot Spectral Alignment Thickness Measurement Program

Point Spectral Contrast Measurement (PSM) technology is an advanced non-contact measurement method that is particularly suitable for thickness measurement of thin materials such as electrode foils. The technique utilizes a point spectral sensor that emits and receives light of a specific wavelength, and accurately calculates the thickness of the electrode foil by measuring the propagation time and intensity changes of the light in the electrode foil.

Measurement principle:

The principle of point-spectral contrast thickness measurement is based on the interference and reflection of light. When light is emitted from a point spectral sensor onto the surface of an electrode foil, part of the light is reflected back, and another part of the light passes through the electrode foil and is reflected on its other side. These two portions of reflected light interfere, forming a specific interference pattern. By analyzing the characteristics of the interference pattern, the thickness of the electrode foil can be determined.

Measurement advantages:

1, high precision: point spectral alignment measurement technology can realize high-precision thickness measurement, the resolution can reach the sub-micron level, to meet the electrode foil on the stringent requirements of thickness accuracy.

2, non-contact measurement: avoid the traditional contact measurement method may cause damage to the electrode foil, but also improve the stability and reliability of the measurement.

3, fast measurement: can be completed in a short period of time on the electrode foil thickness measurement, improve production efficiency.

4, to adapt to the complex environment: temperature, humidity, tension and other environmental factors have less impact, can be in a variety of complex production environment and stable work.

By adopting POMEAS Spot Spectral Alignment Thickness Measurement Program, the thickness accuracy of electrode foils has been significantly improved, and the stability of product quality has been greatly enhanced. At the same time, the production efficiency has been effectively improved due to the realization of real-time monitoring and automated control.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com