High-precision image measuring instrument (flash meter) advantages inventory

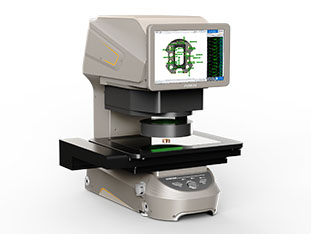

In the field of modern industrial production and quality inspection, high-precision image measuring instrument (flash meter) is playing an increasingly important role, its unique advantages for many industries to bring efficient and accurate measurement solutions.

I. High measurement accuracy

- Advanced optical system: The high-precision image measuring instrument is equipped with a high-resolution optical lens that clearly captures the minute details of the object being measured. Whether it is a complex component outline or a fine electronic component, it can be accurately imaged. For example, in the electronics manufacturing industry, for the size measurement of tiny capacitors, inductors and other components, the flash tester can be accurate to the micron level to ensure product quality and performance.

- Accurate image algorithms: Combined with advanced image processing algorithms, it is able to accurately analyze and process the acquired images. Through edge extraction, feature recognition and other technologies, it can accurately determine the size, shape and other parameters of the measured object, effectively reducing measurement errors. For example, for workpieces with irregular shapes, the flash measuring instrument can quickly and accurately measure their key dimensions, providing reliable data support for quality control in the production process.

- Stable mechanical structure: the instrument's mechanical structure is well-designed, using high-quality materials and advanced manufacturing processes to ensure the stability of the measurement process. In the process of long time use, it can maintain good accuracy stability, not affected by external environmental factors. For example, in the machining industry, for the size measurement of large workpieces, the stability of the flash meter can ensure the accuracy of the measurement results.

II. High measurement efficiency

- Rapid imaging and measurement: the flash meter can quickly complete the imaging and measurement of the measured object in a short period of time. Compared with traditional measuring instruments, it greatly reduces the measurement time and improves work efficiency. For example, in the assembly line of mass production, the flash meter can quickly conduct dimensional inspection of each product, timely detection of unqualified products, improve production efficiency and product quality.

- One-button operation: easy and convenient operation, usually only need to press a button to complete the entire measurement process. The instrument automatically completes the steps of focusing, image acquisition, measurement and analysis, without the need for complex operating procedures, reducing the skill requirements for operators. Even people without professional measurement knowledge can quickly get started.

- Batch Measurement Function: With powerful batch measurement capability, multiple measured objects can be measured at the same time. By setting the measurement parameters and programs, the instrument can automatically perform rapid measurement of batch workpieces, and automatically record and count the measurement results, providing an efficient measurement means for mass production of enterprises.

III. Rich measurement functions

- Multiple Measurement Modes: In addition to the conventional two-dimensional dimensional measurement, it also has a variety of measurement modes, such as three-dimensional measurement, contour measurement, angular measurement and so on. Can meet the measurement needs of different types of workpieces, providing users with a full range of measurement solutions. For example, for parts with complex curved surfaces, the flash tester can accurately obtain their shape and size information through the three-dimensional measurement mode.

- Form and Position Tolerance Inspection: It can inspect the form and position tolerance of the measured object, such as straightness, flatness, roundness, perpendicularity, parallelism and so on. It helps users to fully understand the geometric shape and positional accuracy of the workpiece, and provides an important reference basis for product design and production.

- Data processing and analysis: with powerful data processing and analysis functions, it can display, store and statistically analyze the measurement results in real time. Users can generate a variety of reports and charts as needed to facilitate the management and traceability of measurement data. At the same time, it can also interact with other equipment or systems to realize information sharing and integration.

IV. Strong adaptability

- Wide range of applications: Because of its high precision and high efficiency, flash tester has been widely used in many industries such as machinery manufacturing, electronics, automotive, aerospace, medical equipment and so on. Whether it is the measurement of small precision parts, or large workpiece inspection, flash tester can play a good performance.

- Good adaptability to the environment: able to work normally in different environmental conditions, with strong anti-interference ability. For example, in some poor light, high temperature or a slight vibration in the environment, the flash tester can still maintain stable measurement performance, not affected by environmental factors.

V. High degree of intelligence

- Autofocus and auto-recognition: with autofocus and auto-recognition functions, it can quickly and accurately find the focus of the measured object and automatically recognize the features and edges of the measured object. It reduces manual intervention and improves the accuracy and efficiency of measurement.

- Intelligent Programming and Parameter Setting: It supports intelligent programming, which can automatically generate the measurement program and parameter setting according to the user's needs. Users only need to input the basic information of the measured object and measurement requirements, the instrument can automatically generate the corresponding measurement program, greatly saving programming time and workload.

- Remote control and monitoring: some of the high-end flash meter also supports remote control and monitoring functions, the user can operate the instrument remotely through the network, real-time access to measurement results and instrument status. This facilitates the production management and quality control of enterprises and improves the flexibility and convenience of work.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com