A measurement system is a complex system that integrates a variety of technological components designed to accurately acquire and record the physical characteristics of an object such as size, shape, and position.

1. High-resolution lenses

The lens is the “eye” of the measurement system, responsible for capturing the image of the measured object. The quality and type of lens directly affects the clarity and accuracy of the image. In the measurement system, usually choose a lens with high resolution, low distortion and appropriate focal length to ensure that the captured image can truly reflect the actual characteristics of the object. In addition, the choice of lens also needs to consider factors such as measurement range, working distance and field of view.

2. Machine vision light source

The light source is an indispensable part of the measurement system, which provides lighting to illuminate the measured object to ensure that the lens can capture a clear image. The selection and design of the light source is critical to the accuracy of the measurement results. The ideal light source should provide uniform, stable illumination that is appropriate to the characteristics of the object being measured. In practice, different types of light sources (e.g., LEDs, halogen lamps, etc.) and different illumination methods (e.g., forward illumination, backward illumination, etc.) may be required to meet different measurement needs.

3. Industrial cameras

Camera is the core component of the measurement system, responsible for the lens captured images into digital signals. The performance of the camera directly affects the accuracy and speed of the measurement results. When selecting a camera, parameters such as its resolution, frame rate, dynamic range, and interface type need to be considered. High-resolution cameras can capture more detailed information and improve the accuracy of the measurement; while high-frame-rate cameras can capture images of dynamic objects faster and are suitable for real-time monitoring and high-speed measurement.

4. Multi-functional image measurement software

Software is the “brain” of the measurement system, responsible for processing and analyzing the image data captured by the camera. Through specific algorithms and models, the software can extract the size, shape, location and other key information, and generate the corresponding measurement report. The functionality and performance of the software have a significant impact on the overall performance of the measurement system. Excellent measurement software should have a friendly user interface, powerful data processing capability and high-precision measurement algorithms.

5. Altimeter Sensor

An altimeter sensor is a component of a measurement system used to measure the height or distance of an object. It is usually used in conjunction with lenses and cameras to obtain complete information about an object in three-dimensional space. There are various types of altimetric sensors, including laser rangefinders, ultrasonic sensors, and others. Different types of altimetric sensors have different operating principles and performance characteristics and are suitable for different measurement scenarios. By combining the use of altimetric sensors and image data, accurate measurement of the shape and size of objects can be realized.

The measurement system consists of several key components such as lenses, light sources, cameras, software and height sensors. These components collaborate with each other to achieve accurate measurement of physical characteristics such as size, shape, and position of an object. When selecting and using a measurement system, the performance and parameters of these components need to be considered comprehensively according to the specific measurement needs and working environment.

Measurement systems have a wide range of applications in a number of fields including, but not limited to, glass, hardware, plastic and electronic parts. In the glass industry, measurement systems can be used to detect key parameters such as thickness, flatness, and edge treatment of glass panels; in hardware manufacturing, it can accurately measure the size, shape, and position of parts to ensure that the product meets the design requirements; in the field of plastic parts production, the measurement system is able to monitor the dimensional changes and surface defects of the injection molded parts; and in the manufacture of electronic parts, it is used to detect the semiconductor chip's size, position, and package quality, etc.

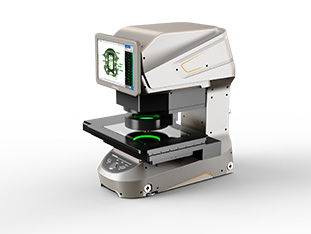

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com