As the electronics industry continues to grow, chip design and manufacturing is becoming more and more sophisticated. A leading semiconductor manufacturing company needs to accurately measure various dimensional parameters of the chip during the chip production process to ensure product quality and performance. However, traditional measurement methods suffer from low efficiency, low precision, and susceptibility to human factors, which cannot meet the enterprise's needs for mass production and high-quality control.

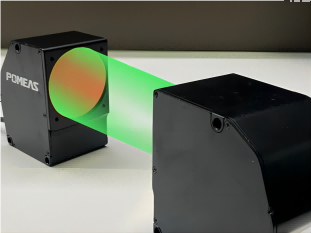

The successful application of POMEAS in-line image measuring instrument in the case of chip size measurement fully demonstrates its important value in the electronics industry. Whether it is chip manufacturing, electronic product assembly or other precision manufacturing fields, in-line image measuring instrument can provide accurate and efficient measurement solutions for enterprises.

Advantages of In-Line Image Measuring Instruments

High precision measurement: POMEAS in-line image measuring instrument adopts high resolution image sensor and advanced image processing algorithm, which is able to realize micron-level measurement accuracy. Tiny dimensional features on the chip, such as line width, pitch, diameter, etc., can be accurately measured to ensure that the chip meets strict design requirements.

Highly efficient measurement: In a mass production environment, efficiency is key. In-line image measuring instruments can quickly acquire an image of the chip and automatically perform dimensional measurement and data analysis, greatly improving measurement speed. Compared with traditional manual measurement, efficiency is increased by several times or even tens of times.

Online real-time measurement: The measuring instrument can be installed directly on the production line to realize online real-time measurement of the chip. By integrating with the production control system, the measurement results can be fed back in a timely manner, allowing companies to monitor quality and adjust production processes.

Easy to operate: POMEAS in-line image measurement system has a user-friendly interface and simple operation procedure, which can be operated without the need of professional measurement technicians. Employees can be trained to use the equipment, reducing labor costs.

POMEAS In-Line Image Measuring Instrument provides powerful technical support for chip production. Its high accuracy, high efficiency and online real-time measurement function help customers realize strict control of chip dimensions and improve product quality and production efficiency.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION